- Home

- Companies

- Solid Applied Technologies Ltd. ...

- Products

- SOLIDAT SonarScan - Model SLDL2810 ...

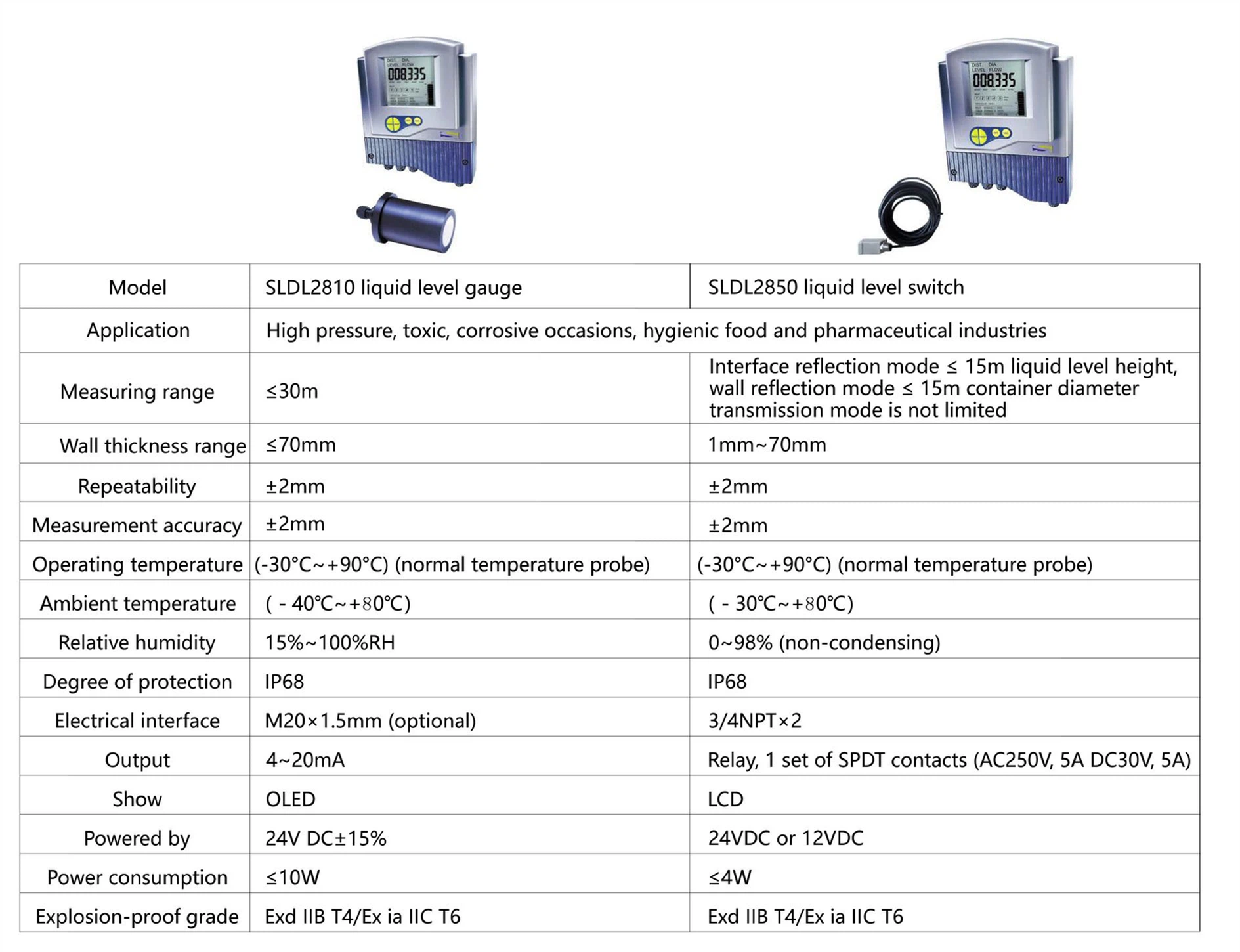

SOLIDAT SonarScan - Model SLDL2810 Series -External Ultrasonic Liquid Level Meter

External ultrasonic liquid level meter is a Non-contact liquid level gauge measuring instrument. The Externally mounted sonar level gauge uses the propagation of ultrasonic waves on the outer wall of the tank and calculates the liquid level through the time difference between reflection and reception. External ultrasonic level meter has the advantages of easy installation, is not affected by the medium, and does not require opening holes. It is suitable for tanks of various shapes and materials, such as spherical tanks, horizontal tanks, vertical tanks, etc.

High measurement accuracy - real-time control of the production process

- ±2mm measurement accuracy

- Provides extremely convenient calibration method

True non-contact measurement

- External liquid level gauge has a measuring range of up to 30 meters

- Measurement blind area can be as low as 30mm

- Extremely low measurement blind zone-full range real-time liquid level tracking

- Anti-precipitation, even if there is a large amount of precipitation, it will not affect the measurement

Simple installation - great savings on your costs

- External ultrasonic is low cost and cost-effective

- Easy to install, debug and operate

- For horizontal tanks, debugging can be eliminated, which greatly saves costs.

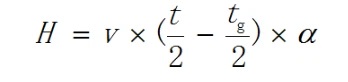

When the Non-invasive Ultrasonic Level Sensor measures the liquid level, the sonar wave signal is emitted from the probe, and after being reflected back by the liquid surface, the echo signal is detected by the probe. The echo signal is processed by a proprietary algorithm to calculate the time t, and the system calculates the liquid level height according to the formula.

Container under test

Various shapes such as spherical, vertical, and horizontal require a probe installation space of 200mm long, 200mm deep, and 300mm high directly below the container. There are no solid structures (transverse partitions, drain plates, columns, stirring), etc. between the installation position of the measuring probe and the highest level of the liquid. The thickness of the tank wall at the bottom of the barrier container (where the measuring probe is installed) is ≤100mm. The bottom wall of the container (where the measuring probe is installed) has no lining or gas jacket. The bottom wall of the container (where the measuring probe is installed) is made of hard material, such as carbon steel, 16MnR, 304.316. Fiberglass, hard rubber, etc.

Liquid to be measured

The dynamic viscosity of the liquid medium being measured is less than 50mPa·s (cP). The liquid does not have serious sedimentation, crystallization and self-aggregation. The liquid cannot suspend a large amount of solids and deposit a large amount of sediment. It cannot be an emulsion and cannot have a large number of bubbles. The liquid to be measured is preferably a single liquid or a miscible mixture. If there are two or more immiscible liquids that will form an obvious interface, the instrument must be specially configured.

Probe installation temperature

The temperature of the tank wall at the bottom of the container (where the measuring probe is installed) determines the appropriate probe to choose. The normal temperature probe ranges from (-30°C to 90°C) and the high temperature range from (60°C to 200°C).