Fäth - Mobile Membrane Filtration System

For many companies in the timber industry, treating process wastewater is a key issue. The aim is to remove heavy metals and salts from the water, and re-use as much of it as possible for other processes.

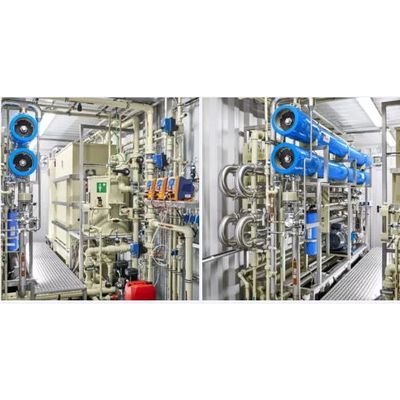

For one of our customers, we built a plant that does just that and is highly impressive in two relevant criteria – efficiency and compactness. It was fitted inside a standard 20 ft shipping container, and equipped with filter racks, pumps, measuring equipment, PP tanks in three different sizes (2000 l, 800 l, 200 l ) as well as a collection tray. The piping was installed in two different pressure stages.

The result is a plant that allows up to 90% of the water to be recovered by combining ultrafiltration with downstream reverse osmosis. The membrane used is cleaned by an integrated CIP (Cleaning in Place) station with a separate CIP cleaning tank.

Range of services:

- 3D design

- Fit-out of a 20 ft shipping container with a collection tray and stainless steel rack

- Installation and fastening of components

- Plastic and stainless steel piping

- Control cabinet construction and electrical connection of sensors

Process parameters:

- Conductivity/pH value

- Pressure/temperature

- Flow rate

Mechanical specifications:

- Fitted in a 20 ft HQ shipping container

- Total empty weight: 3.5 t

- PP tanks (2000 l, 800 l, 200 l)

Electrical specifications:

- Semi-automatic control

- Frequency controlled pumps

- Input voltage: 400 V 3 phase 50 Hz

- Max. input current: max. 80 A