Fäth GmbH products

Modules / Systems

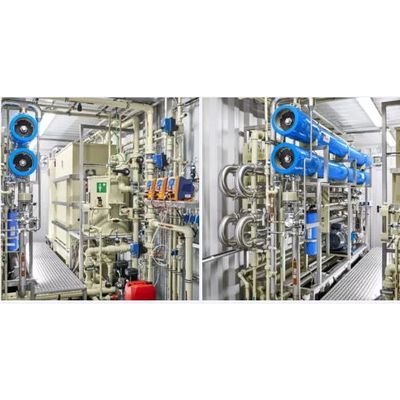

Fäth - Supply module

When developing and building this module, customer-specific space and feature requirements must be considered. The module was also optimised in terms of process technology and installation as part of the development process.

Fäth - Solvent System

This solvent system is designed in accordance with the ATEX directive and is suitable for installation in zones 1 and 2. It has a stainless steel housing with a collection tray and meets strictest requirements in terms of supply security and purity. German supervisory body TÜV approves the plant on-site in Klipphausen.

Fäth - Mixing Systems

Our mixing systems can meter wet chemicals/slurry with utmost precision via weighing scales or to flow fittings. Concentration and process reliability can be monitored dependably via the integrated analysis system. Customers can decide whether to chose semi- or fully automatic operation with a batch mode. The module includes a mixing tank, a day tank and a supply line. The system can also optionally be designed as a loop system.

Custom Plants

Fäth - Mobile Membrane Filtration System

For many companies in the timber industry, treating process wastewater is a key issue. The aim is to remove heavy metals and salts from the water, and re-use as much of it as possible for other processes.

GasServant - Model 800 - Fully Automatic Gas Cabinet

The GasServant-800 is a fully automatic supply system for withdrawal from liquid and pressurised gas cylinders. The redundant design ensures a continuous supply of gas. The system automatically switches between the two supply lines as required. All process parameters are monitored continuously.

Fäth - Diaphragm Valve Test Stand Plant for CIP/SIP Processes

Diaphragm valves are used to distribute and metre fluids in process engineering systems. We developed a test stand to enable our customer Bürkert to efficiently test the stability of the valves they produce. By simulating cleaning cycles, the test stand assesses how valves react to the test media for CIP (Cleaning in Place) and SIP (Sterilization in Place) processes.