- Home

- Companies

- Fair Mekanik Mühendislik San.Tic.Ltd.

- Products

- Fairfield - Ecology Unit - Control ...

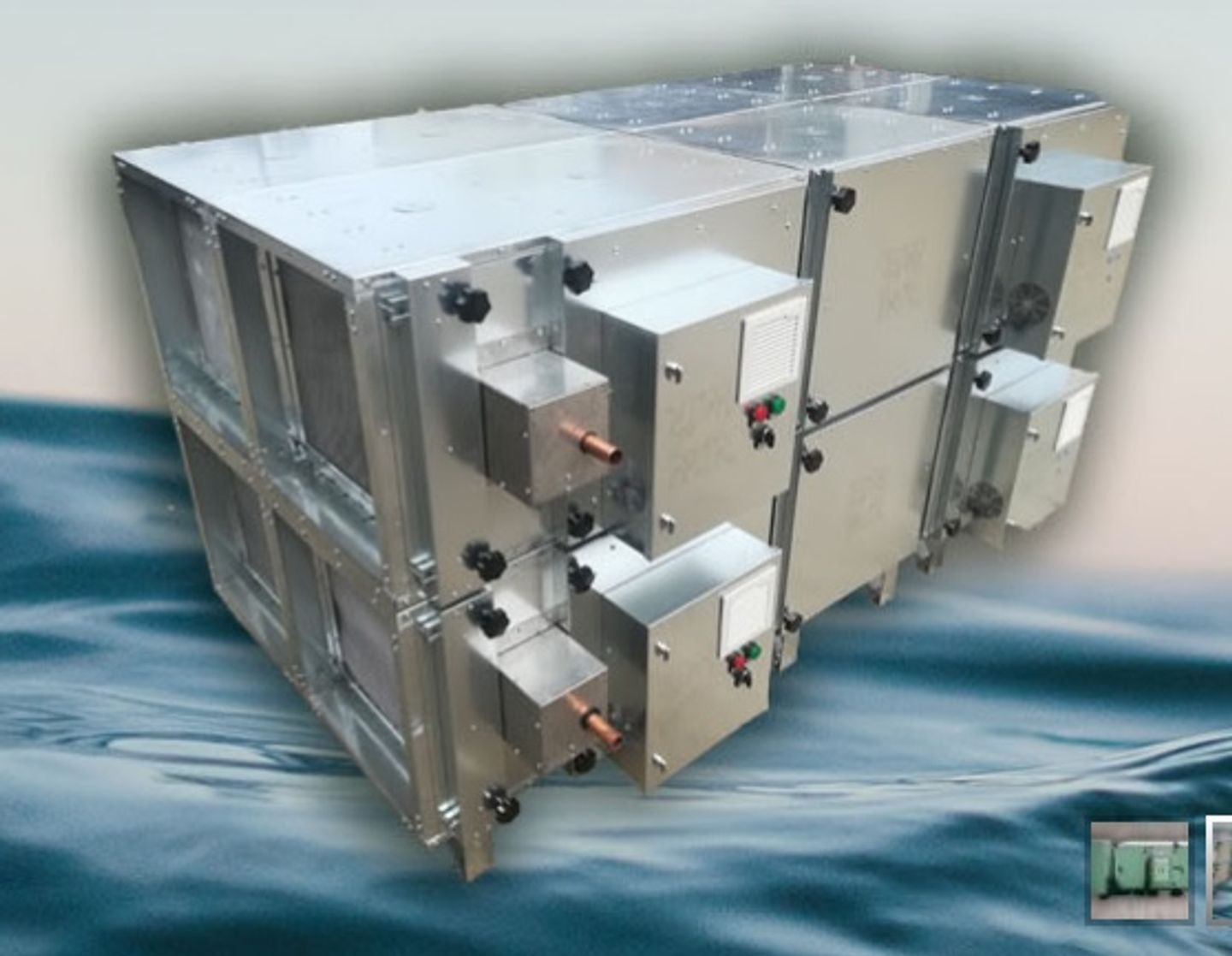

Fairfield - Ecology Unit - Control Panel

The automatic control panel keeps the electrostatic filter and carbon filter efficiency constant. It controls all functions of automatic washing system. Also includes DCV ( demand control ventilation ).

There is a 7” LCD touch screen on the stainless steel cabinet. In a place where the kitchen workers can easily see and reach.

Control panel controls the fan speed is proportionally. Also, user can adjust the speed by slide bar on this screen. Also, it can reach the highest speed with one touch.

Operation and fault information of the Fan Motor can be seen on the display.

The arc protection information is displayed on the LCD screen when the electrostatic filter has an arc protection.

When the electrostatic filter is in operation or malfunctions, the fault information is displayed.

Stainless steel control panel with emergency stop button.

In case of a malfunction of automation system or electrostatic filter, there is a manual start-up fuse inside the panel for forced operation of exhaust fan.

The fan speed switches to temperature-controlled automatic operation after a user-adjustable time. Also, user can adjust the desired temperature via the display. This means DCV, Demand Control Ventilation.

Control panel measures the exhaust air temperature continuously and controls the fan speed automatically. Also, LCD screen shows the instantaneous extract air temperature on the display.

Controls of Automatic Washing System:

- The weekly working hours of automatic washing can be adjusted via the display.

- By using LCD display, user can adjust the power/intensity of automatic washing as required.

- Whenever water temperature is low, an electric heater 10 lt starts on. And then heater tries to catch the appropriate water temperature.

- Automatically adjusts the best washing performance according to water pressure. It works at a pressure of at least 2.5 bar and a maximum of 6 bar. Also, there is an high pressure relief security system for pressure above 6 bar.

- Control panel applies scenarios that reduce the risk of fire. Because of a fire risk the exhaust air temperature goes outside the normal limits. If so, control panel tries to reduce the temperature by maximizing the air flow. And gives alarm at the same time.

- The control panel can communicate with the central automation system via ModBus.

- In addition to the above, the automatic control panel controls the following parameters . And in case of malfunction, fault gives alarms on the display.

Additional Alarms:

- Low network pressure

- High network pressure

- Low water temperature

- Main solenoid valve failure

- Secondary solenoid valve failure

- Cleaning chemicals over warning

- Dosing pump failure

- Water heater failure