- Home

- Companies

- Fluid Components International LLC. ...

- Products

- FCI - Model FlexSwitch FLT93L - Inline ...

FCI - Model FlexSwitch FLT93L -Inline Flow Switch for Multi-Process Sensing & Switching

The FLT93L inline type FlexSwitch for flow and temperature monitoring represents the first true technological breakthrough in thermal technology in over a decade. FCI is the only thermal manufacturer providing temperature compensation to ensure set point accuracy for process temperatures that vary up to ± 100°F. The FLT93L is easily field-configured or factory preset, providing unparalleled flexibility, accuracy and stability for all multiple process sensing and switching requirements.

- Pump protection

- Cooling water/heat exchangers

- Drain line flow

- Safety spray nozzle monitoring

- Oil well system testing

- Relief valve monitoring

For Flow Service - Setpoint Range:

- Water-based Liquids:

0.015 to 50 cc/sec [0.0009 to 3 lps]

- Hydrocarbon-based Liquids:

0.033 to 110 cc/sec [0.002 to 6.6 lps]

- Air/Gas:

0.6 to 20,000 cc/sec [0.036 to 1198 lps]

Accuracy: (whichever reading is higher)

- Liquids: ± 0.5% reading or ± 0.04 fps [± 0.012 mps]

- Gases: ± 0.5% reading or ± 2 sfps [± 0.06 nmps]

For Temperature Service:

- Accuracy: ± 2° F [±1° C]

- Repeatability: ± 1° F [± 0.6° C]

Response Time: As low as 0.5 seconds.

Enclosure: NEMA 4X/IP66 Rated. Standard: Polyester power coated aluminum, with single 1" NPT conduit port. Optional: Stainless steel. Optional: Dual-conduit port, aluminum with 1/2" NPT or M20 metric conduit ports.

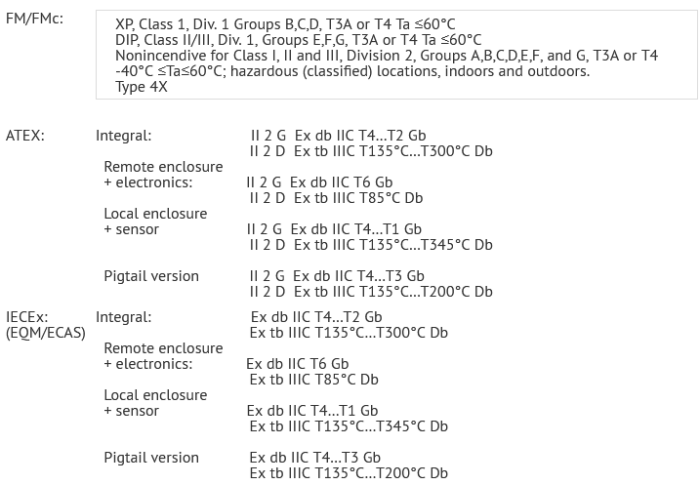

Compliances and Agency Approvals: FM, FMc, ATEX, IECEx, EAC/TR CU, Inmetro. CE mark. PED, CRN.

Meets EC directives for EMC and LVD. Probe complies with Canadian Electrical code requirements of ANSI/ISA 12.27.01-2011 as a single seal device.

Optional N.I.S.T. Flow Calibration Services

Factory N.I.S.T. calibration in air or water is available as an option for customer specified setpoint(s) or a flow curve based on the media ranges specified above.

Flow Element

Materials of Construction: All welded 316L stainless steel for all wetted surfaces.

Process Connection:

- Standard: 1 inch male NPT or 0.75 inch female NPT at tee inlet and outlet

- Optional: Flanges

Inline Tee Length: 3.375 inch [86 mm]

Operating Temperature:

- Standard: -40° to +350° F [-40° to +177° C]

- Optional: -100° to +500° F [-73° to +260° C]

- Operating Pressure: To 3500 psig [240 bar(g)]

Control Circuit

Operating Temperature: -40° to +140° F [-40° to +60° C]

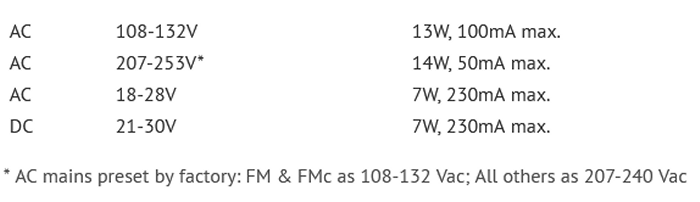

Universal AC/DC supply. Input terminals and jumpers on circut board select specific power.

- Relay Contacts: Field configurable dual SPDT or single DPDT rated 6 amps at 115 Vac, 240 Vac or 24 Vdc. Hermetically sealed relays are available as an option.

- Output Signal: Analog DC voltage related to flow or level/interface signal and proportional to temperature.

- Electrical Connection: 1 inch female NPT

- Remote Configuration: Available as an option with customer specified interconnecting cable length.