Ferox - Emplacement Technology

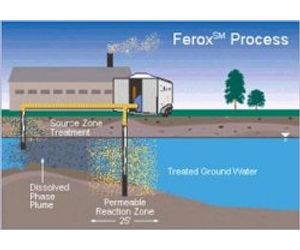

Ferox emplacement technology is a patented, in situ remediation technology developed by ARS which combines a proprietary injection process with the use of a high reactivity Zero-Valent Iron powder. With successful implementations at numerous facilities across North America and Western Europe, we have abundant experience using this technology in varied geologic and site conditions.

The atomized multi-phase injection approach provides several key benefits over conventional injection techniques. These include:

- Aggressive mixing/recirculation maintains the iron powder in uniform suspension and allows for an accelerated reaction of the iron powder with groundwater.

- Providing added moisture necessary for the reaction when applying in an unsaturated zone.

- Allows the iron powder to be injected into the formation to significant radial distances using relatively low pressures (less than 150 psi).

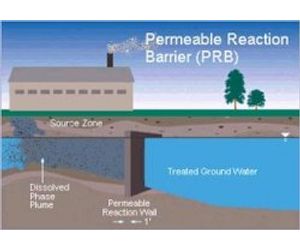

The traditional approach to in situ reduction of chlorinated hydrocarbons or heavy metals using Zero-Valent Iron employs the construction of permeable reaction walls, or funnel and gate systems for continual passive treatment of dissolved phase contaminants. These types of passive treatment technologies are designed to be placed on the down-gradient side of a plume to intercept groundwater flow prior to its migration off-site.

As the dissolved phase contamination flows through the permeable reaction wall, reduction of the hydrocarbons and heavy metals occurs. Though these types of passive treatment systems are simple to apply at shallow depths and for low concentration levels of chlorinated organics, their applicability and cost effectiveness are greatly limited at deeper depths and higher concentrations.

The patented Ferox technology consists of the integration of two commercially proven processes to provide a cost-effective in situ treatment method for groundwater and soils contaminated with halogenated organic compounds, and/or leachable heavy metals.

To apply the Ferox, an open borehole or our direct-push injector assembly casing is used to position the downhole apparatus into the subsurface. Once in place, Zero-Valent Iron powder is injected into the formation as a slurry or as a dry material. Nitrogen gas or compressed air is used as the carrier fluid.