Steklonit JSC

- Home

- Companies

- Steklonit JSC

- Products

- Steklonit Stekon - Fiber-Reinforced ...

Steklonit Stekon - Fiber-Reinforced Plastic Rebar

FromSteklonit JSC

STEKON fiber-reinforced polymer rebar (composite rebar) referstorods made of reinforcing fibers which are impregnated with polymer thermosetting biпding agent and hardened, with transversal or helical ribs made on surface of the rods.

Most popular related searches

water drain

retaining wall

domestic waste

pump station

toxic waste

solid waste toxicity

water pump station

drain pump

solid waste

water treatment plant

Easy installation:

- Use of building machinery may be totally abandoned

- Reduced period of building and assembling works

High resistance to corrosion

- Possibleuseunder exposure to aggressive media

- Possible thinning of protective concrete layer

- Extendedoperationallifetimeof a facility

- Extendedinter-maintenance period

- Reduced expenses for operation of a facility

- Cost effective delivery of material

- Shrunkstorage space for storing the rebars

- Reduced losses when cut to necessary size

- Rebars of greater diameters are produced only as rods

- Any length of rodsor coiling is possible uponagreeingaboutwithacustomer

Coiling is possible

- With its inherent strength performance and its structure being essentially different from structure of steel, fiber-reinforced polymer rebar, if 4 to 12 mm in diameter, can be coiled. As a result, alongside with thereby optimized logistics, storage and installation, butt-joints may almost be avoided while reinforcing framework composed of solid rods.

- Rebars of greater diameters are produced only as rods

- Any length of rods or coiling is possible upon agreeing about with a customer

Cost efficiency

- Assuming apossible calculated substitution of diameters, direct saving would achieve 10-30% o wing to reduced cost of reinforcing framework

- Subject to optimization of building machinery, process savings may be several times greater than direct savings

- footing of residential buildings, industrial strictures and other structural concepts on elastic foundations

- industrial flooring and open platforms for machinery

- hydraulic works (purification and treatment facilities, water sluices and water-draining facilities, pumping stations)

- bridgeworks, berthing and marine facilities

- tunnels structures

- normal and pre-stressed civil structures when constructing monolithic concrete and prefabricated buildings

- structural parts as individual rods

- retaining walls and structures

- load-bearing/non-loadbearing wall elements

- concrete elements and structures on foundation (footings, floors, slabs and etc.)

- bridges

- railroad beds

- fencings

- electric power plants, buildings and facilities involving electromagnetic emission

- building and facilities for storing solid domestic wastes, highly-toxic wastes.

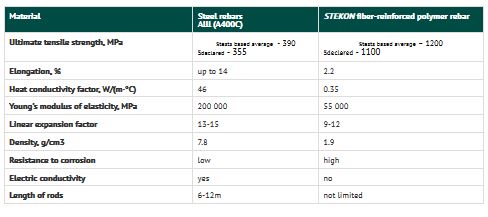

When it comes to a justifying calculation, Ultimate tensile strength, being one of the main characteristics of rebars, gives economical and process benefit at reinforcing a civil structure through substituting metal rebars for equally strong STEKON fiber-reinforced polymer rebar of minor diameter (examples provided in a comparative table below):