- Home

- Companies

- Containment Solutions, Inc., (CSI)

- Products

- CSI - Fiberglass Rehabilitation ...

CSI - Fiberglass Rehabilitation Manholes

Under certain circumstances total structural degradation of pre-cast manholes can occur in less than 5 years. Instead of continuing to patch perpetually corroding concrete, simply reline the existing structure with a CSI fiberglass rehabilitation manhole.

Rehabilitation Manholes can be installed within existing brick or precast manholes to provide a long-term and cost-effective solution to manhole rehab. CSI rehab manholes are manufactured using the same composite and process as standard manholes so they inherently resist the effects of hydrogen sulfide while withstanding HS-20 traffic loads. They meet or exceed the requirements of ASTM D-3753 Glass Fiber-Reinforced Polyester Manholes.

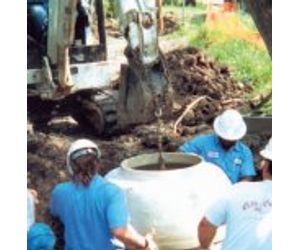

Because of the convenient slide-in method of installation, CSI rehab manholes do not require unearthing older corroding manholes saving you time and money. These newly installed manholes will still carry a 20-year warranty just like standard fiberglass manholes from CSI.

Containment Solutions, Inc., (CSI) Rehabilitation Manholes can be installed within existing concrete, brick or precast manholes to provide a long-term and cost-effective solution to manhole rehab. The CSI Rehabilitation Manhole resists the attack of hydrogen sulfide while withstanding H-20 traffic loads. They meet or exceed the requirements of ASTM D3753-Glass Fiber-Reinforced Polyester Manholes and wetwells.

CSI Fiberglass Manholes were developed in 1972. Since then, thousands of our manholes have been installed throughout the U.S.A., in many different types of soil, and in many different effluents, without a single failure. CSI manholes have stood the test of time.

This should not be surprising. CSI Fiberglass Manholes have the corrosion resistance, strength, monolithic design, and light weight which make them ideal for any manhole application. They can withstand the most severe conditions found in a sewer environment, whether they are under a busy street or a peaceful backyard.

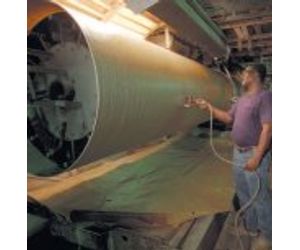

Quality is built into each CSI manhole. We start with a time-proven design which distributes loads evenly to reduce stress. We use only the finest quality resin and glass. Plus, we add chemically enhanced silica to improve corrosion resistance, strength, and overall performance. These materials are then centrifugally cast to form the very best manhole available today.

Containment Solutions is a name you can trust. Formerly a division of Owens-Corning, the world’s largest fiberglass producer, we are committed to

continuing our tradition of excellence. After all, we have been manufacturing underground tanks and manholes for over 30 years and we want to continue to earn your trust, just as we have for over a quarter of a century.

- Corrosion resistance

- Structural strength

- Lightweight

- Monolithic design

- 20-year corrosion and structural warranty

Eliminates Corrosion and Eliminates Costly Maintenance/Rehabilitation

Corrosion is the mortal enemy of ordinary manholes, but not of fiberglass. Even decades of attack by hydrogen sulfide has no effect on CSI fiberglass manholes. As a result, you avoid the street closings, service disruption, and costly repairs and maintenance associated with ordinary manholes.

Structurally Sound – Exceeds H-20 Load Rating

Fiberglass manholes have been in service for more than 30 years. Many of these installations are in busy streets. CSI manholes are designed to

withstand the rigid requirements of AASHTO HS-20 Axle Loads. Based on ASTM requirements, manholes must withstand a minimum dynamic load rating of 16,000 pounds. Meeting this standard means that a CSI fiberglass manhole will withstand far more weight than a fully loaded cement truck.

Ease of Installation

Containment Solutions’ manholes are far lighter than concrete – about 60 pounds per vertical foot. This allows for an easier, safer, and less costly installation. There is no need for heavy equipment. Less manpower is required to move the manhole.

Reduce Infiltration / Exfiltration

Inherent corrosion, structural inefficiency and infiltration are making concrete and brick and mortar manholes obsolete. Infiltration increases water treatment costs. Exfiltration through corroded manholes contaminates the environment. Joints in concrete and brick manholes are a major source of these problems. CSI manholes have no joints. They are available in one-piece lengths from 3 to 25 feet. This prevents infiltration or exfiltration. The monolithic design also makes installation easier by reducing the time necessary to complete joints between sections.