- Home

- Companies

- Propex Operating Company, LLC

- Products

- Fibermesh - Model 650 - Synthetic Fiber

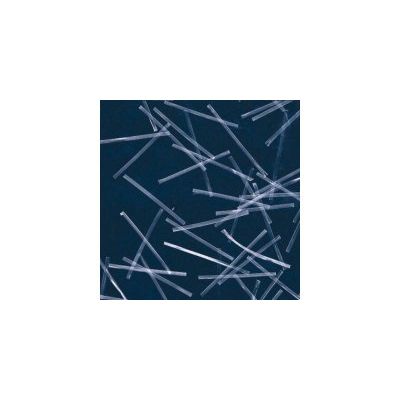

Fibermesh - Model 650 -Synthetic Fiber

Fibermesh 650 is an engineered graded macro-synthetic fiber used for secondary reinforcement for concrete]—an alloy polymer macro-synthetic fiber featuring e3 patented* technology manufactured to an optimum gradation and highly oriented to allow greater surface area contact within the concrete resulting in increased interfacial bonding and flexural toughness efficiency. Fibermesh 650 is specifically engineered and manufactured in an ISO 9001:2000 certified facility for use as concrete secondary reinforcement at a minimum addition rate of 3.0 lbs per cubic yard (1.8 kg per cubic meter). Complies with ASTM C III6/C III6M, Type III fiber reinforced concrete. ^Covered by US Patent # 5628822, 5456752.

- Requires no minimum amount of concrete cover

- Is always uniformly positioned in the concrete and in compliance with codes

- Safe and easier to use than traditional reinforcement

- Saves time and hassle

- Graded macro-synthetic fiber for concrete secondary reinforcement used as an alternate to welded wire reinforcement and light rebar

- Inhibits the formation of plastic shrinkage and plastic settlement cracking

- Provides impact, abrasion and shatter resistance

- Greater surface area provides increased flexural toughness (residual strength)

- Improved ductility

- Provides improved durability

- Control of drying shrinkage and temperature cracking

- Good finishing characteristics

- Pumpable reinforcement

- Slabs-on-ground

- Sidewalks/Driveways

- Parking areas

- Overlays & toppings

- Exterior pavements

- Non-magnetic applications

- Shotcrete

- Composite metal decks

- Absorption : Ni

- Specific Gravity : 0.91

- Fiber Length* : Graded

- Electrical Conductivity : Low

- Melt Point : 324°F(162°C)

- Acid & Salt Resistance : High

- Aspect Ratio : 96.5

Product Use

Mixing Designs And Procedures: Fibermesh® 650 reinforcing is a mechanical, not a chemical process. Due to fiber efficiency, minor mix design modifications may be required depending on the application. Consult your Propex Concrete Systems representative for recommendations. Fibermesh 650 macro-synthetic fiber is added to the mixer before, during or after batching the other concrete materials. Mixing time of at least 5 minutes at mixing speed is required as specified in ASTM C 94.

Finishing: Fibermesh 650 reinforced concrete can be finished with normal finishing techniques in accordance with ACI 304, Section C.3.

Application Rate: The minimum application rate for Fibermesh 650 macro-synthetic fiber is 3.0 lbs per cubic yard (1.8 kg per cubic meter) of concrete. For Shotcrete or specialty concrete performance consult your Propex Concrete Systems representative for specific dosage recommendations.

Guidelines

Fibermesh 650 macro-synthetic fibers should not be used to replace structural reinforcement. Fibermesh 650 fibers should not be used as a means of using thinner concrete sections than original design. For joint spacing, follow industry standard guidelines suggested by PCA and ACL

Compatibility

Fibermesh 650 is compatible with all commonly used concrete admixtures and performance enhancing chemicals.

Packaging

Fibermesh 650 macro-synthetic fibers are available in 1.5 lb toss-in degradable bags. Bags are packed into cartons, shrink wrapped and palletized for protection during shipping.

Technical Services

Trained Propex Concrete Systems specialists are available worldwide to assist and advise in specifications and field service. Propex Concrete Systems representatives do not engage in the practice of engineering or supervision of projects and are available solely for service and support of our customers.

Reference Documents

- ASTM C 94/C 94M Standard Specification for Ready-Mixed Concrete.

- ASTM C III6/C III6M Standard Specification for Fiber-Reinforced Concrete.

- ASTM C 1399 Standard Test Method for Obtaining Average Residual-Strength of Fiber-Reinforced Concrete.

- ASTM C 1436 Standard Specification for Materials for Shotcrete.

- ASTM C 1609 /C 1609M Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading). Replaces ASTM C 1018.

- ASTM C 1550 Standard Test Method for Flexural Toughness of Fiber Reinforced Concrete (Using Centrally Loaded Round Panel).

- JCI-SF4 Method of Test for Flexural Strength and Flexural Toughness of Fiber Reinforced Concrete.

- ACI 304 Guide for Measuring, Mixingjransporting and Placing Concrete.

- ACI 506 Guide for Shotcrete.