- Home

- Companies

- J.U.M. Engineering GmbH

- Products

- J.U.M. - Model 3-500 - FID Total ...

J.U.M. - Model 3-500 -FID Total Hydrocarbon Analyzer

The J.U.M Heated Total Hydrocarbon Analyzer Model 3-500 FID is our lowest cost alternative to continuously measure the total concentration of hydrocarbons within a gaseous sample. This can be ambient air, exhaust gases from a combustion process e.g. stack emissions, from any type of an industrial vent, from an internal combustion engine, or from any other emission containing hydrocarbons. The 3-500 is based on our time proven 300A FID platform of which we have sold thousands of analyzers. The 3-500 fully complies with EN 12619, EN 13526 (EU), with 2. BImSchV, 13. BImSchV and 17. BImSchV, (Germany) and with EPA Method 25A and Method 503 (USA). It can be used as a table top instrument but is ideally suited to be integrated in CEMs.

- Made in Germany

- All critical components including pumps, sample filters, detectors and main electronics are manufactured in house

- Fully heated to 190 degree C

- Typical sensitivity 0.01 ppm CH4

- Direct concentration (e.g. ppm) display allows to read up to 3 decade ranges without range change

- Internal sample pump and air pump

- Internal combustion air supply (No external air cylinder needed)

- Very low fuel consumption (less than 20 cc/min @ 100% H2)

- Disposable sample filter in rear panel

- Automatic ignite capability (optional)

- Automatic flame out alarm contact and fuel shut off

- Sample pressure regulator not in contact with sample gas

- Multiple range capability, 5 selectable ranges are standard

- 19" rack mount unit, only 132 mm high

- Stack gases (CEM) and all other Environmental and process applications

- Air and gas scrubber efficiency

- Process chemical gas analysis

- Personnel safety

- Solvent recovery

- Catalytic converter and thermal combustor testing

- Automotive and engine emissions

- Fence line (perimeter) monitoring

- Non-methane hydrocarbon measurements

Methane Only Option

The available Methane Only Option provides the capability to measure METHANE ONLY or TOTAL HYDROCARBONS. The choice is switch selectable from the front panel or by remote contact closure.

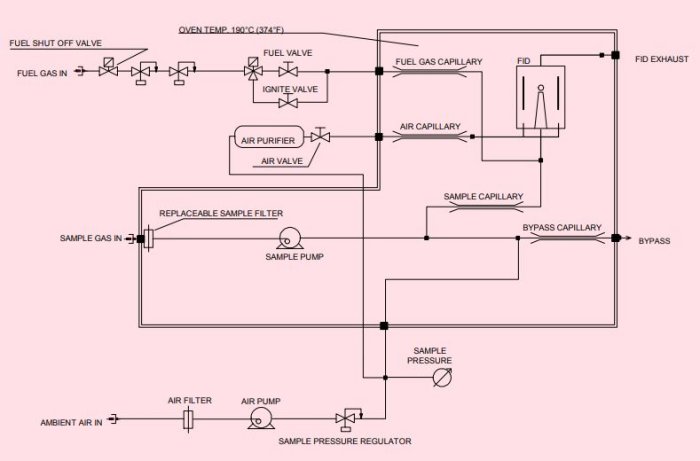

The Flame Ionization Detection (FID) method is used to determine the presence of total hydrocarbon concentrations in a gaseous sample. Burning hydrocarbon-free hydrogen in hydrocarbon-free air produces a negligible number of ions.

Once a sample containing hydrocarbons is introduced into this flame a very complex ionization process is started. This process creates a large number ions. A high polarizing voltage is applied between the two electrodes around the burner nozzle and produces an electrostatic field. Now negative ions migrate to the collector electrode and positive ions migrate to the high voltage electrode. The so generated ionization current between the two electrodes is directly proportional to the hydrocarbon concentration in the sample that is burned by the flame. This signal is measured and amplified by our electrometer-unit.

A sample pressure regulator provides a controlled back pressure at the sample capillary which gives admittance of a constant sample flow rate to the burner. This technique without the conventional back pressure regulator is used by J.U.M. Engineering for over 30 years to provide the highest possible sample flow rate stability and lowest maintenance. Our compactly designed flow control module for controlling the fuel and air flow rates via needle valves use high precision pressure regulators. The needle valves are factory adjusted and sealed to ensure the optimization of the burner.

- Method of analysis: Flame Ionization Detector

- Sensitivity: Max 1 ppm CH4 full scale

- Response time: Approx 02 seconds

- T90time: 1 second

- T90 time with heated line (75m) and filter: less than 8 seconds

- Zero drift:

- Span drift:

- Linearity: Up to 10000ppm within 1% FSD

- Oxygen synergism: <12%FSD

- Measuring ranges (ppm): 0-10,100, 1000, 10000, 100000, others on request

- Signal outputs: RS 232, 0-10 VDC and 4-20 mA

- Display: 6 diqit enqineerinq unit

- Sample pump: approx 25 l/min capacity @ operating temp

- Sample Filter: 2 micron change filter

- Zero and span adjust: Manual on front panel

- Fuel consumption 100% Ffe: approx 20 ml/min @ 15 bar (22 psig)

- Fuel consumption 40%H2/60%He: approx 90 ml/min @ 15 bar (22 psig)

- Burner air consumption: built in burner air supply

- Oven temperature: 190°C(374°F)

- Temperature control: u-processor PID controller

- Power requirements: either 230VAC/50Hz, 850 W or 115VAC/60HZ, 850 W

- Ambient temperature: 5-43°C(41-110°F)

- Dimensions (WxDxH): 19"(483mm)x460mmx132mm

- Weight: approx 20 kg (44 lb)

J.U.M. reserves the right, at any time and without notice, to change specifications presented in this data sheet and assumes no responsibility for the application or use of the devices described herein.

- AMU 35: Automatic range change

- AZM35: Automatic flame ignition and re-ignition

- DCC35: Dual concentration alarm w. individual adjustable threshold and alarm outputs

- LT0 35: Measurement of low trace hydrocarbon levels. Requires external, zero grade combustion air supply!

- MBP35: Integrated bypass pump

- PDA 35: Sample pressure monitor with alarm

- RCA 35: 0-20 mA analog output instead of 4-20 mA

- RCC35: Remote control range change

- RCIO 35: 0-20 mA analoq output, galvanically isolated

- RCI4 35: 4-20 mA analog output, galvanically isolated

- TPR35: EXTERNAL temperature controller for heated sample line, e.g. JUM TJ100

Availability of options may change unannounced! Please contact us before specifying your purchase order!