- Home

- Companies

- Progress Eco S.A.

- Products

- Progress Eco Pro-Slot - Flat Panels of ...

Progress Eco Pro-Slot - Flat Panels of Wedge Wire Screens

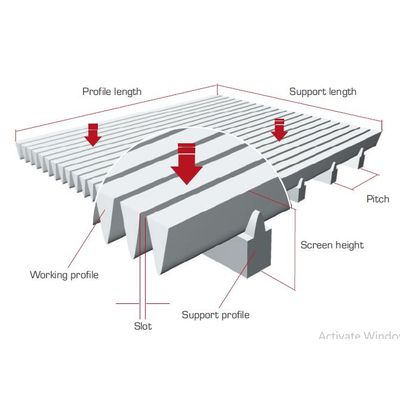

Flat panels of wedge wire screens are manufactured by welding special profiled working wires to support wires at an angle of 90 degrees. A precise slot is received by means of applying modern welding technology between working wires and support wires. The result is a rigid screen construction with the capability of withstanding heavy loads.

Innovative solutions of technology allows:

- to control quality of welding

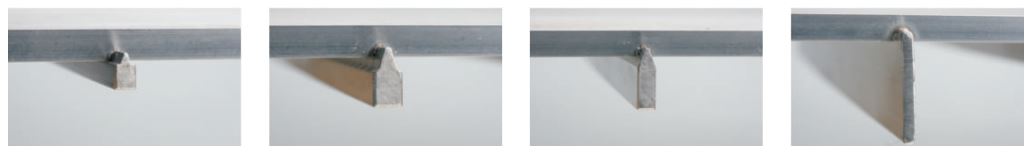

- to use various working wires

- to design various slot sizes in one screen

- to design various support wires in one screen and

- various distances between support wires in one screen

- to gain superior flatness of sieves (no corrugation of working wires between support wires)

- Slot: from 0,05 mm

- Maximum size: 3500 x 4000 mm

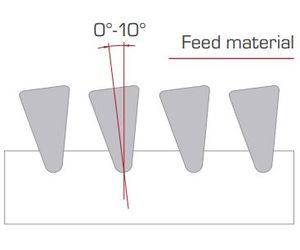

- Profile tilt: 0°-10°

Length and width

- ≤ 500 mm: ± 2 mm

- > 500 mm and ≤ 2000 mm: ± 3 mm

- > 2000 mm: ± 4 mm

Slot opening

- ± 0,050 mm

- max. deviation ± 0,100 mm

Screen hight:

- ± 0,3 mm

Diagonal

- ≤ 500 mm: ± 2 mm

- > 500 mm and ≤ 1000 mm: ± 3 mm

- > 1000 mm and ≤ 2000 mm ± 4 mm

- > 2000 mm ± 5 mm

Flatness:

- 4,00 mm/m

Straightness:

- 4,00 mm/m

* Different set of tolerances needs individual agreement

An important parameter of the screen is the open area. Open area Fo(%) is the relation of the slot surface to the total screen

surface. Open area is calculated according to the following formula:

F0 = S/(S+A) x 100 (%)

A– width of the working wire ( according to the table of working wires)

S – slot size

For example:

A sieve was made of working wire Sb 28 with slot s = 0,24 mm

F0 = 0,24/(0,24+2,2) x 100% = 9,6%