Flexco - Rivet Solid Plate Fastening System

The Flexco Rivet Solid Plate Fastening System is recommended for high-tension applications, with a staggered, multiple-point attachment for a long-lasting hold. Ideal for use with straight-warped belts because rivets separate the fibers instead of displacing the carcass.

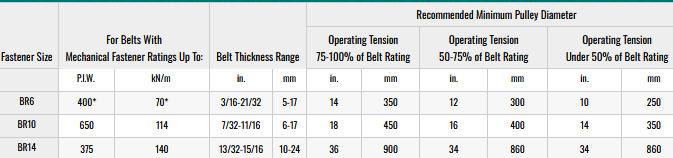

- Mechanical fastener rating from 400 to 800 PIW (70 to 140 kN/m)

- Belts from 3/16” to 15/16” (5 mm to 24 mm) thick

- Pulley diameters from 14” to 36” (350 mm to 900 mm)

- Low-profile, Scalloped Edge® design is conveyor component compatible

- Wide, heavy-gauge plates promote long wear life, with a sift-free splice

- Rivet-attached for maximum resistance to pull out

- Compatible with troughed belts

FASTENER METALS AND AVAILABILITY

To maximize fastener service life, fastener material must be matched to the application. Flexco manufactures fasteners from a broad range of materials. Our selection makes it easy to specify a fastener that will deliver maximum performance in a variety of conditions—from wet and abrasive applications to highly corrosive environments.

Galvanized Steel: For basic applications, galvanized steel is recommended. It is magnetic, offers good abrasion and rust resistance, but is not recommended for corrosive environments.

Stainless Steel: Stainless steel provides extra resistance to abrasion, magnetic attraction, and corrosion from acids and other chemicals.

MegAlloy®: Features superior resistance to wear and abrasion. Provides several times the service life of steel. Not recommended where impact of corrosion is a problem.

Everdur: A corrosion-resistant copper and silicon alloy. Fully non-magnetic and spark-free, low in resistance to abrasion.