- Home

- Companies

- Lyndex Recycling Systems Limited

- Products

- Lyndex Middibite - Flexible Baler

Lyndex Middibite - Flexible Baler

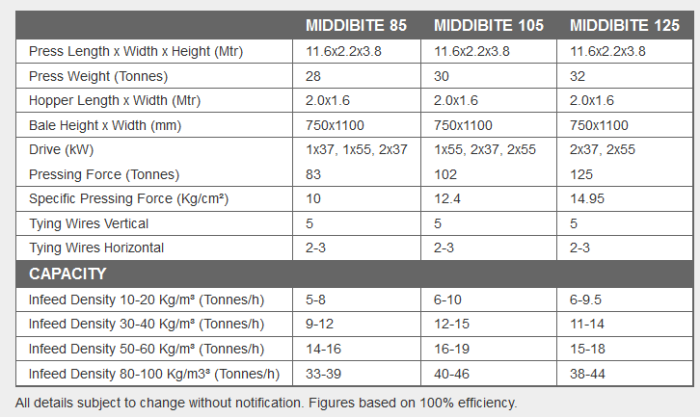

Following the success of the Meggabite, Lyndex can now offer all the benefits and advantages of this patented shear and pre-compression design with a 750 x 1100mm bale. Plus, for difficult materials, the tying system has five wires. All these features and advantages are brought to you in the ‘Middibite Range’.

Pre-Compressions Flaps

The pre-compression flaps are used to increase the infeed density when processing low density materials such as plastics. Which result in higher throughputs.

Also when processing bulky high density material the pre-compression flaps are used to push the material below the blade level making processing easier.

- Main cylinder sizes: 85 - 125Tonne

- Power units: 1x37 - 2x55kw

- Hopper size: 2000x1600mm

- Bale size: 750x1100mm

The all welded construction from thick shot blasted plate guarantees long life, extra vertical ribs in the pressing area to contain all of the pressing forces. The compact design with vertical tying system ensures minimum floor area requirement.

All areas subjected to heavy wear are protected by easily exchangeable bolted wear parts, thus extending the life of the wear parts and reducing operating costs.

Key assemblies are machined where precision is required and the structure is assembled in jigs to ensure tolerances are maintained.

When baling plastic or bulky material, a 2 or 3 wire horizontal tying system can be added to hold the baled material together in uniform bales, reducing expansion.