Lyndex Recycling Systems Limited products

Baling

Lyndex Meggabite - Multi Purpose Baler

Lyndex Recycling Systems Limited design and development team looked to develop a multi-purpose baler that could process all types of material without problems. The result was the development of the Meggabite. The Meggabite contains all of the developments from the Bimax shearing press with the addition of two pre-compression flaps.

Lyndex BIMAX - Balers

The ‘Bimax’ model of baler is renowned in the recycling industry for reliability, productivity and longevity. This high quality machine is manufactured by Lyndex of Telford with state-of-the-art control systems.

Lyndex Bigro - Medium Volume Baler

The Lyndex (formerly Lindemann) Bigro is a medium volume baler which produces 750mm high x 1100mm wide, high density bales. The Bigro is a long established design that has been improved and updated over many years.

Lyndex Middibite - Flexible Baler

Following the success of the Meggabite, Lyndex can now offer all the benefits and advantages of this patented shear and pre-compression design with a 750 x 1100mm bale. Plus, for difficult materials, the tying system has five wires. All these features and advantages are brought to you in the ‘Middibite Range’.

Lyndex - Large Heavy Duty Baling Press

High performance heavy duty baling press for processing MSW, plastic, RDF, non-ferrous, paper and cardboard.

Shredding

Lyndex - Confidential Shredder

The Lyndex PZA confidential shredder is ideal for shredding entire files; all confidential papers; bundled, glues or lose without problems. In short: the PZA will shred confidential documents of all grades into any of three preselected particle sizes. By the manually operated valve control one can hydraulically adjust the desired shred size even while the machine is running. With this confidential shredder you are fully equipped to cope with today`s and the future`s confidential destruction requirements. Adjustable shred sizes (dependent on the type of material and the extent of wear of the shredder tools).

Lyndex - Shredder Machines

Lyndex conditioners of the PC range are designed to open up, loosen, and coarsely shred very dense and difficult material, such as bundles of newspapers and magazines, as well as coarsely shred cardboard boxes, corrugated cardboard etc. Even bale discs from compressed paper bales can be re-opened. The shredding and conditioning process spreads the material evenly across the entire width of the press box, increases the filling density of bulky material as well as the output of the baler, and at the same time improves the bale density, bale shape and stability.

Lyndex - Paper Shredders

Lyndex PCZ paper shredders are designed not only to loosen up and tear open the input materials but also to shred them. All advantages are retained, i.e. low energy costs, minimum dust emission, and minimum destruction of fibre structure. The material is only shredded to the extent to achieve bales of stable shape and high density. As with the PC paper conditioner, the PCZ increases the infeed density and thus the press output when used on bulky, voluminous material.

Bag Opener

The Lyndex bag opener has been developed to open black bag waste making it easier to further process the contents via a sorting system. The machine can be conveyor fed or with an extension hopper fed from a grab or bucket loader. The speed of the rotor is controlled via a variable speed drive unit which makes the machine very flexible in operation. Hardox blades on the rotor force the bags to be a fixed anvil there by opening the bags and extracting the material onto the output conveyor.

Conveying

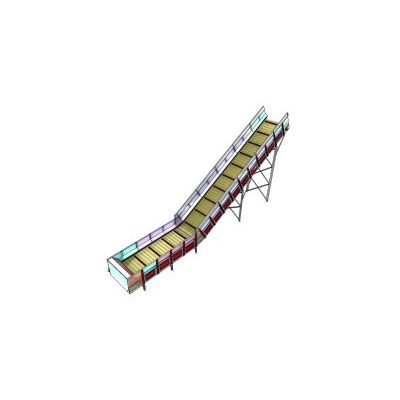

Lyndex - Chain Belt Conveyors

Chain belt conveyors can be designed to widths of up to 2.5 metres and drive chain strengths to suit the application. Chain belt conveyors can be fitted with rubber or steel belts, all chain belt conveyors are heavy-duty welded construction, complete with high quality bearings and gearboxes. All chain belt conveyors can be fitted with variable speed controls.