- Home

- Companies

- Meurer Research, Inc. (MRI)

- Products

- MRI - Flocculation Systems

MRI - Flocculation Systems

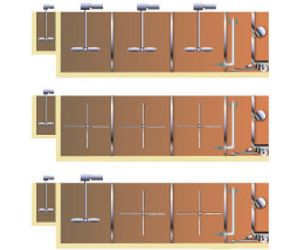

Flocculation is the gentle mixing designed to accelerate the rate of particle collision, which causes the agglomeration of electrolytically destabilized colloidal particles into settleable sizes. MRI combines turbine, horizontal, and hydraulic flocculators for maximum pretreatment control. With increasingly stringent regulations and adoption of membrane filtration, the pressure is on for all stages of pretreatment — chemical feed, flocculation, sedimentation, and filtration — to act in concert. In response, Meurer Research, Inc. has developed MRI Flocculation Systems™ — integrating turbine, horizontal, and hydraulic flocculators into multi-stage systems with a self-cleaning hydraulic final stage, maximizing versatility and performance.

Performance Advantages

MRI’s innovative multi-stage flocculation system eliminates the trade-offs typically associated with G-value turbulence and delivers maximum control and efficiency every pretreatment stage. Only MRI’s multi-stage flocculators leverage the maximum G-value range — from 2,000 to 0.

MRI Flocculation Systems include:

- Extremely high-G vertical turbine mixers for rapid mix stage

- High-G vertical turbine for first-stage flocculation

- Mid-G horizontal paddle wheel mixers for second and third stages

- Extremely low-G hydraulic mixer for combined final stage and buffer zone

- MRI Ultra-Scraper with hinged bottom plank for final stage sediment clean-up

- Ported or serpentine baffles for stage separation

- Option to mix & match for enhanced effectiveness

MRI combines vertical, turbine, paddle wheel, or hydraulic flocculation to fine-tune flocculation.

Hydraulic Final Stage alleviates clarifier turbulence.

Employed in the final pre-sedimentation stage, MRI’s Hydraulic Final Stage:

- Quiets turbulence and creates a buffer zone that offers new lows in G-values

- Consumes zero energy and is low maintenance

- Enables more aggressive mixing in the mechanical stages

- Eliminates the need for high rpm’s in final pre-sedimentation stage

- Is self-cleaning, utilizing a patented hinged bottom plank* to allow a scraper mounted to the MRI Sludge Collector to remove incidental sediment

Vertical Turbine Flocculators deliver a wide variable range.

Flexible and efficient, MRI’s Vertical Turbine Flocculators:

- Provide high collision rates while using less energy

- Have a unique drive on each paddle to allow more versatile mixer speeds and flow directions

- Include a self-cleaning, low-G final hydraulic state

Horizontal Paddle Wheel Flocculators provide mid-range G-values.

MRI Paddle Wheel Flocculators provide consistent floc production in varying water conditions and temperatures. See all the benefits of the MRI Paddle Wheel Flocculator.

Special chemicals accommodate seasonal water conditions.

MRI partners with specialty chemical manufacturers to provide superior ability to accommodate seasonal changes in raw water conditions.

Hydraulic Flocculators Provide Low Energy Consumption and Simplicity

With considerable experience in baffle manufacturing, MRI designs hydraulic flocculators proven to use less energy than their mechanical counterparts, while operating with greater simplicity and flexibility.

To overcome the narrow range of flows of traditional hydraulic flocculators, MRI’s innovative model features a self-adjusting design that provides constant G-factors during fluctuating flow conditions, when desired.