Fote - Magnetic Separator

Magnetic separator machine is suitable to separate magnetite, pyrrhotite, roasted ore, ilmenite and other materials, the granularity of which are below 3 mm. And it is also suitable in coal, non-metallic minerals, building materials and other materials for iron removal operation. Magnetic separator is one of the aircrafts which is widely used in industries.

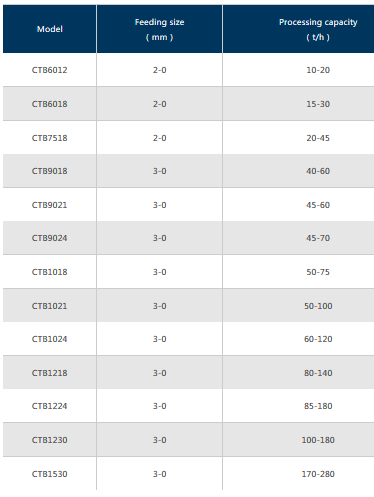

- Processing ability: 1–220 t/h

- Feeding size: 3–0 mm

Shell diameter : 600–1500 mm

Why Choose US?

- 1. The strength of magnetic field is large in the surface of tube;

- 2. Large wrap angle of magnetic system;

- 3. The strength of magnetic field is stable;

- 4. The transmission system is stable and reliable;

- 5. Significantly improve the grade of ore before it enters the mill.

- The strength of magnetic field is large in the surface of tube;

- Large wrap angle of magnetic system;

- The strength of magnetic field is stable.

The pump enters into the mining area of the cell through ore box under the force of water flow. Magnetic particles form into magnetic ball or linkage with the force of the magnetic field. The magnetic ball and linkage are absorbed on the drum during they are moving towards the magnetic pole with the magnetic force. When the magnetic ball and linkage are rotating with the moving drum, because of alternating polarity and magnetic stirring, the gangue and other non-magnetic ore mixed in magnetic ball and linkage are fall down, while magnetic ball and linkage are absorbed on the surface of the drum. These are concentrates we need. The concentrates come to the field where the magnetic is the weakest with the rotating drum. Then they fall in to concentrate slot by the water flow. But the full magnetic roller uses brush roll to discharge ores. At last, the non-magnetic or weakly magnetic minerals are discharged out of the cell with plump.