- Home

- Companies

- Friess GmbH

- Products

- Friess - Model Skimmtelligent - Oil ...

Friess - Model Skimmtelligent -Oil Separator

FromFriess GmbH

The FRIESS Oil Separator used when tramp oil causes an emulsion. Our specially developed Oil Separator is used wherever tramp oil mixes with the process liquid and does not float. Most popular related searches

oil separation

tramp oil

water disposal

wash water

coalescing separator

oil skimmer

magnetic filter

diaphragm pump

industrial gear pump

skimmer

What innovative technology does the FRIESS Skimmtelligent come with?

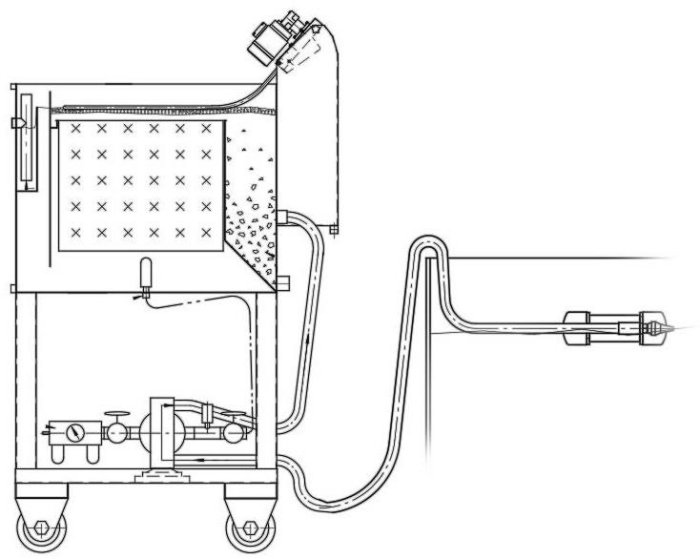

The working medium is pumped through the Skimmtelligent in a bypass flow via a diaphragm pump. In the first stage, the coarse dirt that is also conveyed settles. The tramp oil then collects in the Coalescence Separator until it develops sufficient buoyancy to float to the surface of the liquid.

There it can be removed by a FRIESS oil skimmer into a collection tank, while the de-oiled liquid flows back into the working tank via a drain chamber.

Optionally, it is possible to integrate a FRIESS Magnetic Filter. This can additionally filter out ferritic particles down to a size of about 1 µm from the liquid.

Skimmtelligent 10 / 20 / 40

- Flow rate: 300 l/h / 600 l/h / 1200 l/h

- Oil Capacity: max. 30 l/h

- Operating temperature: 40/70 °C

- pH-value: 5 – 14

- Dimensions: Skimmtelligent 10 / 20 / 40:

- Width: 440 / 440 / 510 mm

- Lengths: 600 / 900 / 1660 mm

- Height: 1200 / 1280 / 1230 mm

- Capacity of the tank: 100 l / 200 l / 400 l

- Treatment Volume: approx. 7500 l / 15000 l / 30000 l

- Friess technologies are robust and proven thanks to industrial gear motors and pumps.

- Reliable removal of large and even the smallest amounts of tramp oil.

- The Friess Skimmtelligent significantly increases the service life of emulsions and washing water.

- Dispose of less emulsion concentrates or detergents.