Hunan New Frontier Technology Co., Ltd.

- Home

- Companies

- Hunan New Frontier Technology Co., Ltd.

- Products

- Frontier - Electrode System

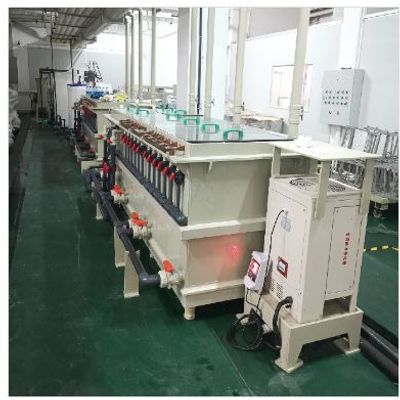

Frontier - Electrode System

New Frontier Tech`s diamond electrode system processes micro-etching waste by simultaneously recovering copper and regenerating sodium persulfate. Using diamond`s unique electrochemical properties (highest oxygen evolution potential and most negative hydrogen evolution potential) as the anode within a specialized ion membrane cell, it oxidizes sodium sulfate back to sodium persulfate in the anode chamber while reducing copper ions to metallic copper at the cathode. The treated solution contains <0.5g/L copper ions and >100g/L sodium persulfate - ready for direct reuse in the etching bath.

Most popular related searches

precious metals recycling

copper recovery

resource recycling

zero discharge

metal recycling

wastewater treatment

precious metals recycling system

wastewater copper

liquid waste

metal recycling system

- The equipment uses a diamond electrode plate as the anode, which can synthesize sodium persulfate, electrolyze copper at the cathode, reduce copper ion concentration, and recycle the regenerated micro etching solution, saving the cost of adding sodium persulfate and sulfuric acid in the micro etching solution tank and production process.

- Recovering copper into high-quality and high-purity electrolytic copper plates, producing electrolytic copper every ten days, with a single electrolytic copper plate weighing over 15 kilograms and a copper recovery rate of 100%. Electrolytic copper can be sold directly, with significant economic benefits.

- Zero discharge of micro etching waste liquid greatly reduces the pressure of environmental protection treatment. Save the cost of liquid alkali required for treating micro corrosion waste liquid, neutralizing sulfuric acid, and precipitating copper ions in wastewater treatment stations.

- The equipment has a small footprint, low investment, no need for other auxiliary materials, simple and easy operation, low operating costs, and significant economic benefits.

- Regeneration of microetching solution, synthesis of sodium persulfate, recovery of electrolytic copper plate and precious metal recycling.