Hunan New Frontier Technology Co., Ltd. products

BDD - Electrode

Frontier - Boron-Doped Diamond (BDD) Electrode Material

Through innovative breakthroughs in boron-doped diamond (BDD) thin-film technology and solutions to traditional technical challenges, we`ve developed a new generation of high-performance BDD electrode materials available in multiple specifications. This achievement results from our rigorous manufacturing process featuring precise pretreatment, controlled plating parameters, and optimized post-plating treatments.

BDD - Testing Equipment

Frontier - Beaker-Type Wastewater Treatment Equipment

The Beaker-type wastewater treatment equipment consists of two BDD anode electrodes and three titanium cathodes. When in use, the module is placed in a beaker and stirred with a magnetic stirrer. The single treatment capacity is 1 L. It can be used for small-scale testing and analysis experiments, which is simple, convenient, economical and practical. CE-certified easy to operate lab-scale BDD electrochemical inert organic pollutant degradation device stock available.

Frontier - Baffle Type Wastewater Treatment Equipment

The module of the baffle type wastewater treatment equipment is based on BDD electrodes and adopts an internal baffle flow channel design, which not only increases the contact area between the solution to be treated and the electrode plate, but also promotes electrochemical reactions more effectively, ultimately achieving the goal of efficient degradation.

BDD - Wastewater Degradation

Frontier - Model EAOPs - Boron-Doped Diamond (BDD) Wastewater Treatment Module

The environmental persistence and toxicological impacts of organic pollutants in wastewater represent one of this century`s most pressing ecological concerns. Contemporary wastewater treatment systems employ electrochemical advanced oxidation technologies (alternatively termed electro-oxidation processes) for practical applications across multiple sectors.

Frontier - Boron-Doped Diamond (BDD) Electrode Electrocatalytic Oxidation Tank-Type Reactor Module

This BDD electrode electrocatalytic oxidation tank-type reactor module is made of PP material injection molding. The material has good strength, is resistant to strong acids and alkalis, corrosion, and high temperatures of 100 degrees Celsius. It has better sealing effects and stronger pressure and impact resistance.

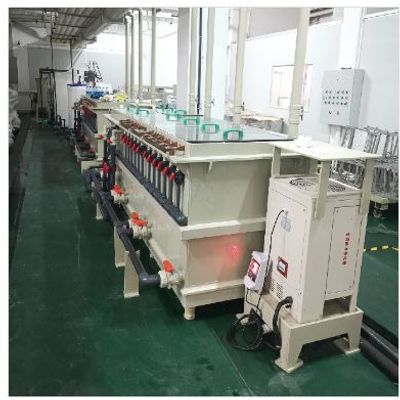

Frontier - Integrated Tank-Type Equipment

The overall equipment is based on BDD electrodes and adopts a slot type integrated design, integrating water inlet device, circulation and filtration device, drainage and exhaust device, exhaust device, power supply and electronic control system, etc. The equipment body is integrated in an integrated chassis, which is equipped with universal wheels for flexible movement. Solved the technical problems of traditional equipment in water pretreatment, low reaction efficiency, and discharge, and achieved intelligent automation.

BDD - Ozone Generator

Frontier - Model CYQ-003 - Ozone Generator

New Frontier Tech`s CYQ-003 ozone water generator uses BDD electrode technology to create powerful hydroxyl radicals and ozone through low-voltage water electrolysis, delivering chemical-free disinfection with minimal byproducts. Compared to corona discharge ozone generators, our compact system produces no harmful nitrogen oxides (NOx). BDD ozone water technology can be widely used in various fields such as household water supply pipe disinfection, domestic water disinfection, and daily life infection control. Electrolysis of water to produce ozone active water is currently recognized as an easy-to-install, maintain, safe and effective ozone water technology. BDD electrodes have extremely high oxygen evolution potentials and are recognized as the most stable and durable electrosynthetic material. Safety, environmental protection, high efficiency, and wide application are the significant advantages of BDD electrode disinfection technology.

BDD - Resource Recycling

Frontier - Electrode System

New Frontier Tech`s diamond electrode system processes micro-etching waste by simultaneously recovering copper and regenerating sodium persulfate. Using diamond`s unique electrochemical properties (highest oxygen evolution potential and most negative hydrogen evolution potential) as the anode within a specialized ion membrane cell, it oxidizes sodium sulfate back to sodium persulfate in the anode chamber while reducing copper ions to metallic copper at the cathode. The treated solution contains <0.5g/L copper ions and >100g/L sodium persulfate - ready for direct reuse in the etching bath.

Vacuum Coating

Frontier - Model JJP Series - Winding Coating Machine

Our winding coating system utilizes either suspension coating or roll coating technology to achieve scratch-resistant substrate surfaces with uniform film layers. The equipment incorporates an optimized cooling structure that prevents substrate deformation during coating processes.

Frontier - Model DH Series - Multi-Arc Ion Coating Machine

The equipment has the advantages of a high deposition rate, firm combination, and stable operation. Based on traditional multi-arc technology, the Company has made strict improvements and design in target sealing structure, magnet, and cooling, which improves ionization rate, refines particles, firmly combines the film layer with the substrate, makes the film layer more compact, and improves hardness and wear resistance.