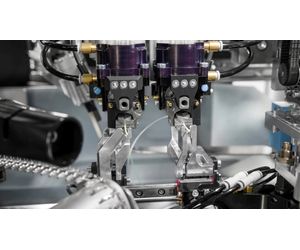

Komax Sigma - Model 588 -Fully Automatic Twisting Machine

The Sigma 588 enables fully automated, high-performance production and output of twisted cables, including crimping, sealing, and intelligent wire shifting for any open end configuration. The Sigma 588 is the first stage of fully automated twisted cable production with cross-sections from 0.22 mm² to 2.5 mm², tailored to meet the needs of various production volumes with high quality demands. It offers essential options such as crimping, sealing, and a full range of Quality Tools, including the intuitive Komax HMI user interface. The machine twists two individual wires into a UTP cable, a common requirement in the automotive industry. Its modular design allows for easy upgrades with additional crimp and seal modules which allows customization to meet specific customer needs. The machine's intelligent, fully automatic wire position adjustment for open ends ensures highly efficient production with open end lengths ranging from 40 mm to 99 mm.

Tailored to production needs

With a 2+2 station configuration and all essential quality control tools, the Sigma 588 is ideally suited for high-volume production.

The variable open end (VoE) processing set offers intelligent and integrated wire position adjustment for a wide range of open end configurations.

The on-site changeable processing set of the Sigma 588 allows for both large wire gauges and smaller open end configurations.

Automation minimizes operator influence and reduces human errors, while Q1250 algorithms control the production and ensure high quality results.