- Home

- Companies

- GEA Bischoff GmbH

- Products

- GEA Bischoff - Heavy Metal Separation

GEA Bischoff - Heavy Metal Separation

The off-gas of metallurgical processes such as copper smelters or zinc roasters are containing a high load of heavy metals, for instance lead (Pb), copper (Cu), chrome (Cr), nickel (Ni), cadmium (Cd), mercury (Hg). Most of these heavy metals are particulates, which are precipitated in the gas cleaning plant, mainly consisting of dry precipitator, scrubber and wet precipitator.

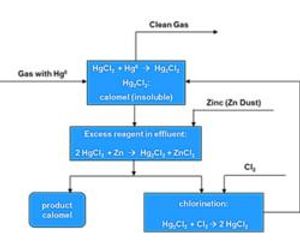

Metallic mercury (Hg0) forms a vapor, which is removed by the Calomel process which is a continuous hydrometallurgical procedure, where the gases are treated with an acidified solution of Hg++ - chloride complexes dissolved in water at temperatures of 25 – 40°C.

During the purification of the gases on mercury, insoluble Hg2Cl2 is formed. The Hg2Cl2 is separated from the solution by decantation. Some of the produced Hg2Cl2 is re-oxidized to HgCl2 by a separate process. This HgCl2 is added to the recycled wash solution as compensation for Hg++ which is consumed by the reaction with metallic mercury vapor and by minor side reaction.

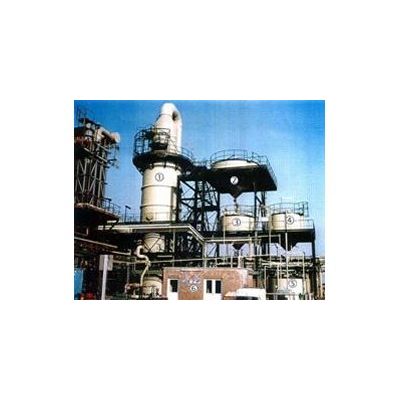

Legend

- Mercury Removal Reactor

- Primary Settling Tank

- Secondary Settling Tank

- Storage Tank

- Chlorination Tank

- Chlorine Dosing Station