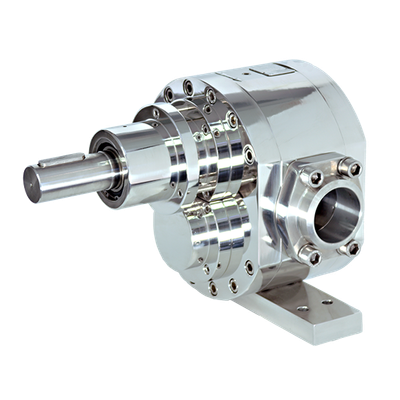

Pompe Cucchi - Model N Series -Gear Metering Pump

This series of metering gear pumps was designed to allow for the production of the components of steel bar pumps. The N-series pumps were designed to satisfy all those applications where, in addition to a constant pressure, a considerable precision in metering is also required.

The total absence of pulsations in the delivery pressure optimizes the quality of the reading of the flow meters, a promptness in response to changes in the flow rate always ensures a correct and precise metering; these factors are essential in the management of a plant and in maintaining the qualitative characteristics of the pumped product.

The construction of this series of gear metering pumps complies with the 2006/42/CE, 2014/30/UE, 2014/35/UE directives and with the UNI EN ISO 12100, UNI EN ISO 13732-1, UNI EN 809, UNI EN ISO 14847 standards. On request, versions compliant with the 2014/34/EU (ATEX) directive and with the API 676 – NACE MR0175 standards; it is also available with EAC (CU TR 010) – CU TR 012 certification.

The management of the quality system of Pompe Cucchi Srl operates in accordance with the UNI EN ISO 9001: 2015 standard.

Metering in the chemical sector for the manufacture of soaps and liquid detergents.

Metering in the chemical sector of toxic, polluting and dangerous liquids.

Metering in the cosmetic sector for the production of shampoos, creams, shower gels, etc.

Metering in the food sector of flavors, juices, melted butter, royal jelly, jams, etc.

Metering in the textile sector of water, acids, bases.

Metering in the industrial sector of products with viscosity values between 1 and 100,000 cps.

SPECIAL VERSIONS

On request we can make special solutions in Titanium, Hastelloy C, Sanycro 28, PVDF, or in any other material that can be worked by machine tools.

Motion is supported through graphite bushings and shims (on request they are also available in loaded PTFE – or silicon carbide). In this way, the impossibility of seizures in case of dry running is guaranteed. In addition, this device allows for total maintenance of the pump directly on the system without the aid of equipment or adjustments.

It is possible to provide an external by-pass valve on the delivery duct. Made of AISI316L stainless steel, they are available in four different sizes (VE1 – VE2 – VE3 – VE4) with threaded connections from ½” up to 1½”, calibration pressures 3 ÷ 15 bar. Also on request, preheating chambers which are suitable for superheated water or diathermic oil can be applied.