- Home

- Companies

- Senix – a division of BinMaster Sensors ...

- Products

- Senix ToughSonic - Model 100.03 Range, ...

Senix ToughSonic - Model 100.03 Range, 30mm Thread -General Purpose Stainless-Steel Ultrasonic Sensors

The ToughSonic®-100.03 general-purpose ultrasonic sensors measure liquids and distances in ranges up to 3 ft. Minimal deadband and durable stainless-steel housings offer precise, durable performance. Choose 30mm threaded mounting and RS-485 or RS-232 outputs.These rugged, compact ultrasonic sensors live up to the “ToughSonic” name. Versatile liquid level sensors feature heavy-duty electronics that are epoxy potted into 316 stainless steel housings.

The TS-100 features permanently attached cables and rugged piezoelectric transducers. Use the TS-100 to monitor & control water and benign liquid levels, measure distances, or detect objects.

- Versatile Measurement Capabilities: Accurately measure distances, detect objects, and monitor water and benign liquid levels

- Robust Construction: Built to withstand harsh conditions, ideal for both indoor and outdoor use

- Wide Operating Temperature Range: Function effectively in temperatures from -40° to +70°C

- High Ingress Protection: Rated IP68, NEMA-4X, and NEMA-6P for superior resistance against dust & water

- User-Friendly Adjustments: Easily configure settings with the included SensorView™ software for setup, testing, and cloning sensors

- Extended Range, Minimal Dead Zone: Achieve precise distance measurements with a long-range capability and a short dead band

- Reliable in Any Environment: Unaffected by optical factors such as color, transparency, or lighting conditions

- Easy Setup & Calibration: Configure effortlessly via PC or onboard button for quick deployment

- Adjustable Sensitivity: Fine-tune detection for precise performance

- Built-in Temperature Compensation: Ensures accurate readings across fluctuating temperatures

- Fast & Simple Installation: Mount with ease for quick deployment in any application

- Rugged, Sealed Housing: Designed for wet, dirty, and harsh environments

- Reliable I/O Protection: Features short-circuit and overload protection for enhanced durability

- Multi-Sensor Synchronization: Operate multiple sensors without interference

- Non-Contact: Accurately measure levels and distances without touching the material being measured

- Rear Status Indicators: Easily monitor sensor operation and diagnostics, or reset default setup using a rear push-button (N/A on TS-100.50), or the push-button can be disabled

- Tank Level Measurement: Accurately monitor liquid levels in tanks containing benign fluids

- Open Channel Flow Monitoring: Ideal for flow measurement in flumes, weirs, and open channels

- Roll Diameter Measurement: Precisely gauge material roll diameters for manufacturing and processing

- Loop Control & Slack Detection: Maintain optimal material tension in production lines

- Object Detection & Presence Sensing: Verify object presence or absence in designated areas

- Relative Positioning: Measure an object’s position relative to a fixed reference point for automation and alignment

- Legacy Part Numbers: TSPC-30S2-485 and TSPC-30S2-232

- Maximum Range: 3 ft. (91 cm)

- Optimum Range: 1.75 to 24 in. (4.5 to 61 cm)

- Deadband: 0-1.75 in. (0-4.5 cm)

- Temperature: -40° to 158°F (-40° to 70°C)

- Humidity: 0 to 100% operating

- Protection: NEMA-4X, NEMA 6P, IP68

- Transducer: Ruggedized piezoelectric

- Compensation: Temperature compensated (selectable in SensorView™)

- Resolution:

- Serial data: 0.0034 in. (0.086 mm)

- Analog steps: 4099 (0-10 VDC)

- 3279 (4-20 mA)

- Repeatability:

- Nominal 0.2% of range @ constant temp.

- Affected by target, distance, environment

- Update Rate: 20 Hz (50 ms), SensorView adjustable; affected by SensorView filter selections

Output

- Output #1:

- Default: 4-20 mA; SensorView configurable

- Alternate: Configure as a switch output

- Output #2:

- Default: Voltage, SensorView configurable

- Alternate: Configure as a switch output

- Voltage Output: 0-10, 0-5 VDC or SensorView configurable; 10 mA maximum

- 4-20 mA Current Loop: Current sourcing, SensorView configurable; maximum loop resistance 450Ω

- Switch Output(s):

- Output #1 and/or #2 can be a switch

- Each can be sinking (NPN) or sourcing (PNP)

- Max ratings: 150 mA @ 40 VDC

- Each has adjustable setpoint, polarity, hysteresis, window, time delays and more

- RS-232 or RS-485:

- Modbus & streaming protocols

- 9600-115200 baud (configurable)

- 8 data bits, 1 stop, no parity

- RS-485 permits multi-sensor networks

- Part number determines interface

- Sync Feature: Permits multiple sensors to operate in close proximity without cross-talk; not usable concurrently with serial data

Mechanical

- Housing: 316 stainless steel for corrosion resistance; usable in salt water, H2S environments

- Mounting (30 mm): Through hole in bracket or panel, two jam nuts included; stainless & nylon brackets and adapters to 1-1/2 in. and 2 in. NPT available

- Attached Cable: 6.5 feet (2 meters), PUR jacketed; custom lengths available

- Standard models: 6-wire shielded + drain

- Serial data only models: 4-wire + drain

- Total Weight:

- 10.4 oz (0.29 kg)

- Includes 6.5 ft. (2 m) cable

* Specifications are subject to change without notice.

Compact. Innovative. Utilized in the roughest conditions.

ToughSonic®-100 series non-contact sensors feature heavy-duty electronics, stainless steel housings and ruggedized piezoelectric transducers to ensure long-lasting accuracy and efficiency, both indoors and outdoors.

Made in the USA, ToughSonic ultrasonic sensors automate liquid level measurement, provide distance ranging, protect expensive assets, and enhance safety.

Choose ToughSonic-100 sensors for accurate non-volatile liquid level measurements in a variety of industries, and in indoor, outdoor, and environmental conditions.

All sensors include serial data communications to connect with SensorView™ software or your equipment.

RS-232 or RS-485 Format

- Selectable Modbus (Default) or ASCII streaming protocols

- Baud rates from 9600 (Default) to 115200 bits per second (bps)

- Many other features adjustable using SensorView

- Multi-sensor Modbus-addressable RS-485 networks

- Better noise immunity in industrial environments

- Allows longer cable lengths at higher baud rates

- Analog 0-10 VDC and 4-20 mA

- Configurable as Sinking (NPN) or Sourcing (PNP) switch

- TWO concurrent outputs with serial data for TS-100.12, TS-100.14

- FIVE concurrent outputs with serial data for TS-100.30, TS-100.50

- Serial data communications available with RS-232 and RS-485

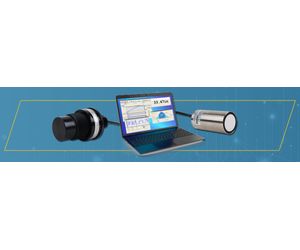

Set up your sensors and inventory management system with SensorView™.

SensorView is included at no charge. It runs on Windows PC and connects to sensors via a serial data port.

Our setup kits provide everything you’ll need to connect through a USB port, including a power supply, sensor-PC interface, and cables.

Over 80 Parameters to Customize

- Analogs: Slope, distance endpoints, analog value limits

- Switches: Set points, window features, time delays

- All Outputs: Power on, loss of echo, loss of sync responses

- Serial Data: Communications, SYNC modes and functions

- Measurements: Temperature compensation, sensitivity, data filters, measure rate, gain settings and data processing filters

- Adjustments: Stored in-sensor memory, accessible even when power is off

All Models Except ToughSonic®100.50

- In situ setup without the use of a computer

- Set analog output endpoint distances

- Establish switch on and off distances

- Set switch polarity & measurement rates

- Synchronize multiple sensors in SYNC mode

- Activate—or deactivate—temperature compensation

- Restore sensor to factory default