- Home

- Companies

- Franz Ziel GmbH

- Products

- Franz Ziel - Model GTS - Glove Testing ...

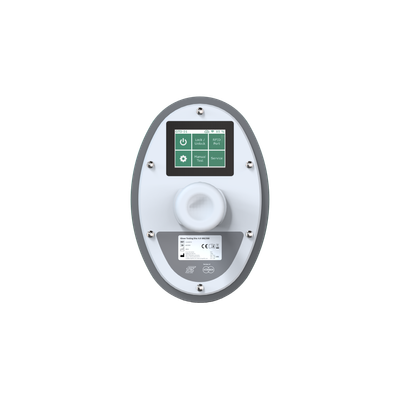

Franz Ziel - Model GTS -Glove Testing System for Isolators and RABS

The Glove Testing System (GTS) offered by Franz Ziel is designed to support aseptic processing technologies in isolator and Restricted Access Barrier Systems (RABS) environments. This system facilitates wireless and tubeless leak testing of gloves, which are a critical component in containment barrier systems due to their direct contact with operators during aseptic manipulations. The GTS ensures compliance with the guidelines from Draft Annex 1 by offering a methodology suitable for integrity testing, including both the barrier systems and the glove systems. Implemented with the latest software technology, the GTS provides a flexible solution that is fully integrable as part of glove management. It emphasizes routine and frequent leak testing to maintain system integrity and prevent product contamination. The GTS is available in various configurations including standalone, customer server integration, and autonomous versions to cater to different operational needs.

The Glove Testing System enables for Annex 1 compliant wireless and tubeless leak testing of gloves installed in Isolators or RABS.

The GTS with the latest software technology offers an extremely flexible and fully integrable solution for glove testing as part of glove management.

Gloves constitute the most susceptible link in the containment barrier systems. Gloves are the most critical part in aseptic manufacturing environment because they are in direct contact with the operator and for aseptic manipulations hence gloves are the main source of potential contamination.

A faulty Glove can breach the integrity of isolator and contaminate the product.

According to Draft Annex 1 ‘’Integrity testing of the barrier systems, and leak testing of the glove system and the isolator should be performed using a methodology demonstrated to be suitable for the task and criticality. The testing should be performed at defined periods, at a minimum at the beginning and end of each batch, and should include a visual inspection following any intervention that may affect the integrity of the system’’

Routine and frequent leak testing of glove/sleeve system is highly recommended. FZ provides one stop solution for protection of your gloves and products.

- Server-Client-Solution

- Active Directory

- Multiple testing of gloves (WLAN)

- Audit Trail

- GAMP 5

- CFR21 Part 11 compliant

- Batch reports

- Fast and reliable pressure decay method

- detects glove holes down to 50 microns

- automated identification and detection of glove port

- Simultaneous tests of all gloves with overall process time in less than 30 minutes

- customizable access levels and easy and reliable data management

- Easy and user-friendly operation via touch-screen display

- Optional calibration and tracking system