Just as you wouldn’t use stainless steel in structural applications (carbon steel would be the steel of choice), you wouldn’t use Graphene Oxide or Multi-layer Graphene as a anode in a battery cell – the results would be disastrous. And why pay the premium of Monolayer Graphene when Multi-layer Graphene will provide nearly the same advantages as a fraction of the cost. Choosing the correct Graphene grade (and ensuring it is as advertised) is the most critical step to a successful Graphene application. Let American Carbon help you determine how to best utilize graphene in your specific application, or follow the links on the left to a number of different projects we are working on independently.

American Carbon Company

- Home

- Companies

- American Carbon Company

- Products

- ACC - Graphene Applications in Advanced ...

ACC - Graphene Applications in Advanced Materials

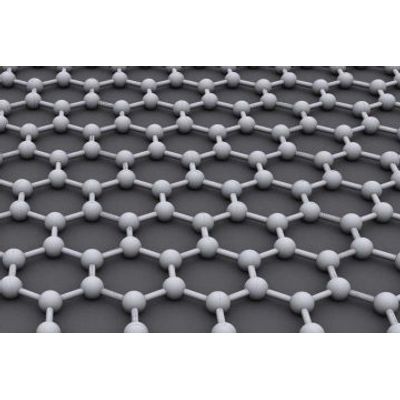

American Carbon is at the forefront of this emerging nano-material. Our team of researchers and product developers have been working with a number of laboratories, product manufacturers, and end-users to develop products that are economically viable for commercial applications in today’s market. There is no doubt that graphene is on a trajectory to significantly change the world as we know it today. By strict definition graphene is a one atom thick nano particle connected in a honeycomb lattice structure. When compared to steel, it is over 100 times stronger by size (and a University of Massachusetts study found it may be able to absorb as much as 10 time more energy before failing) When compared to copper, graphene is much more electronically conductive (although much more brittle). And finally, graphene is rewriting Fournier’s law of thermal conduction which defines how a solid absorbs heat. While these three amazing discoveries are impressive by themselves, the nearly invisible nature of the structure leads to nearly unlimited applications to better everyday products from electronics to lubricants to coatings and even water treatment.