GAB Neumann GmbH

- Home

- Companies

- GAB Neumann GmbH

- Products

- GAB-Neumann - Graphite Quenches

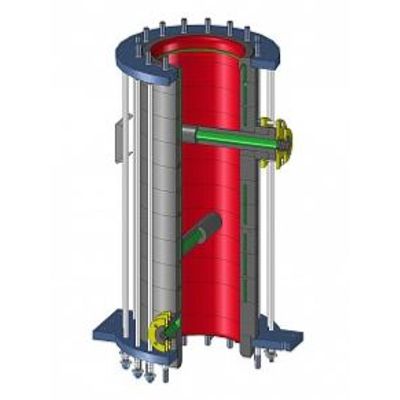

GAB-Neumann - Graphite Quenches

FromGAB Neumann GmbH

Quenches are used in various industries to instantaneously cool down hot gases coming from kilns, ovens, incinerators, and other flue gas sources. Graphite quenches are adapted to the rapid cooling of ultra-corrosive hot gases (up to 1300°C inlet temperature) and prevent the re-synthesis of dioxins and furans. Quenches are gas liquid contactors used to achieve mass and heat transfer between a continuous gas phase that might contain pollutants or/and dispersed solid particles and a dispersed liquid phase. GAB Neumann offer spray, pipe, or Venturi graphite quenches.

Most popular related searches

air pollution control

carbon fiber

air pollution

flue gas

ASME pressure vessel

incineration flue gas

corrosive gas

digital temperature controller

industrial cooling

surface safety

Materials:

- Impervious graphite: GAB GPX1, GPX1T or GPX2

- Pressure plates and flanges: carbon steel or stainless steel

- Tie rods, nuts, bolts, washers, springs: stainless steel

Design:

- Modular design: diameter, height, number of lances and spray nozzles can be adjusted.

- Maximum diameter: 900 mm

- Impervious graphite sections discs with straight flow channels on process side and annular grooves on service side.

- Graphite nozzles on product and utility sides

- Thermal expansion compensation ensured by tie rods and helical springs

- Carbon-fiber reinforcement (optional)

Key Features:

- Design pressure: -1 barg (full vacuum) to +3 barg (45 psig)

- Design temperature: -60 to +200°C (-76 to 392°F)

- Hot exhaust gases up to 1300°C inlet temperature

- Design: according to European PED, ASME code, Chinese Pressure Vessel code and other national pressure vessel codes on request

Optional features:

- Carbon fiber reinforcement

- Outstanding corrosion resistance

- Instantaneous cooling

- Huge liquid-gas interfacial area

- Perfectly adapted liquid distribution design

- Efficient cooling of the quench walls even in the top section

- Low pressure drops

- Low water consumption compared to other designs and materials

- Low total cost of ownership compared to other designs and materials

- Impregnation before machining ensures resin free surfaces

- High operational safety

- Sturdy and modular design

- Short lead time

- Long lifetime

- Instantaneous cooling of flue gases coming from kilns, ovens, or incinerators

- Quenching of hot exhaust gases up to 1400°C inlet temperature

- Air pollution control