- Home

- Companies

- Harmony Enterprises, Inc.

- Products

- Harmony - Insite Technology for Indoor ...

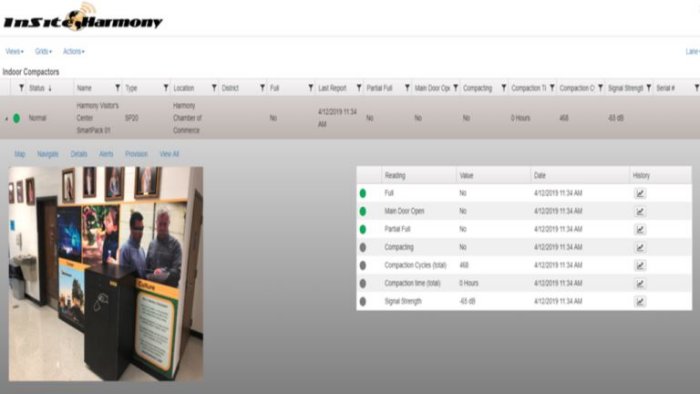

Harmony - Insite Technology for Indoor Compactors

Insite technology for indoor compactors like our SmartPack Automatic Compactor and our 450SS Indoor Stainless Steel Compactor eliminates the need for your staff to physically check on your indoor compactor.

Insite will send you an email or SMS text message alerting you of these conditions:

- Partial Full

- Compactor is Full

- Main Door Open

- Compactor Unplugged/Not Reporting

- Cell Signal Strength

You will have ability to monitor your equipment online for other important information such as compaction cycles and compaction time. You can do this from any device at any time and manage your assets on a “just in time” basis.

With the reporting that this state-of-the-art service can provide, you will increase the life of the equipment, reduce unnecessary labor, schedule the most efficient hauling, and stay proactive with preventive maintenance. All reports can be exported in a variety of user-friendly formats.

Our private network servers provide safety and security from external threats and ransomware. Insite Technology can be used via cellular connection, ethernet connection, or Wi-Fi.

All Insite customers have the ability to create IoT Scenes of their assets that include master dashboards of a larger group of assets.

Harmony`s Insite Monitoring System provides a Total Solutions Approach to compactor monitoring!

Insite not only monitors container fullness, but it can track the overall health of the compactor, and help with preventive maintenance planning!

Insite Technology for Indoor Compactors uses invisible sensor technology to measure accurate compactor fullness, regardless of your fullness setting!

- Can be installed on any Harmony Indoor Compactor, including our SmartPack, 300, 450, 700SS Stainless Steel, AC30 Indoor

- Packer, and our C36TC High Rise Compactor System.

- Utilizes invisible sensor technology to determine accurate fullness levels.

- User friendly cloud-based dashboard that can be used on any smart device.

- Date/time stamp for each compaction cycle.

- Counts total number of compaction cycles.

- Sends an email or SMS text message when the container is partially full, full, has the door left open, or is not communicating.

- This allows your staff to empty the trash on a "just in time" basis, and focus FTE`s on other important tasks.

- Allows you to monitor multiple locations at one time. All Insite customers have the ability to create customizable IoT Scenes of their assets that include master dashboards of a larger group of assets.

- Creates valuable reports to help you track data such as total number of compactor cycles, average cycles per day, average weight, average energy used, etc.