- Home

- Companies

- Cleveland Cascades Ltd.

- Products

- Cleveland - Model C - Head Chute Dust ...

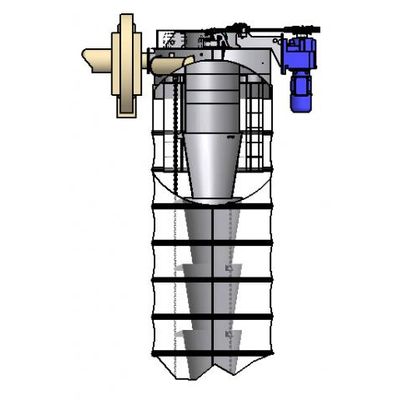

Cleveland - Model C -Head Chute Dust Extraction System

The system has been developed in conjunction with Donaldson Filtration Systems, the leading global specialist in Filtration Technology. It is integrated in to the head chute and comprises a fan motor, compressed air manifold along with up to nine filters & diaphragm valves which are controlled via an Integrated Pulse Controller (IPC).

The system operates by the 0.55Kw motor providing the extraction through each of the filters inside the chute. The manifold allows each filter to clean itself intermittently with a burst of compressed air. Whilst one fan is performing a pulse-clean, the remaining eight are operating so that performance is never compromised. The extracted dust is taken away through the fan, or dropped back through the chute following each pulse-clean, to ensure a loading process with minimised dust emissions.

It can be used in various loading applications where dust control devices are not already installed to the on-site loading system, such as Open Vehicle & Tanker Loading. It is fitted to Cleveland Cascades Free Fall Cone chute systems and can be specified to meet various international standards such as IP65 as well as for use in areas with potential explosion risk, to ATEX standard.