- Home

- Companies

- Tef - Cap Industries Inc.

- Products

- Tef Cap's - Model FEP 1.6:1 - Heat ...

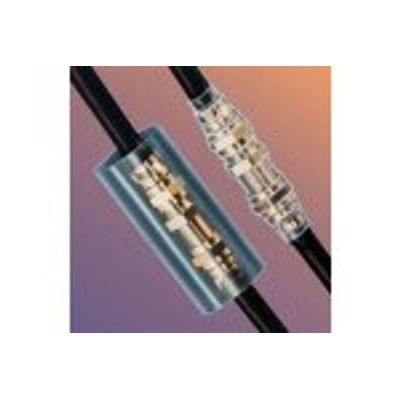

Tef Cap's - Model FEP 1.6:1 -Heat Shrink FEP Tubing

FEP 1.6:1 Heat Shrink Tubing (Fluorinated Ethylene Propylene) is a low cost alternative to the 4:1 Heat Shrink PTFE Tubing. Designed with FDA and Biocompatible resins Heat Shrink FEP Tubing has excellent release properties as well as having great optical clarity. FEP 1.6:1 ( or 1.67:1 ) is manufactured with a higher than normal shrink ratio for FEP Tubing allowing it to slip over nuts, fittings and flanges so that complete assemblies do not have to be removed and taken apart. Heat Shrink FEP Tubing 1.6:1 helps reduce the down time required to apply a Heat Shrink FEP Product and Sleeving.

FEP 1.6:1 Heat Shrink Tubing is designed to shrink on parts that are greatly uneven in size yet still allowing for a one piece containment. FEP 1.6:1 Heat Shrink material covers a large range of product sizes but is limited in the smaller diameter parts.

When shrinking FEP tubing generally all that is needed is a heat source that is able to generate 230F. In some situations ovens can be used but you must not put parts directly into a hot oven. Both parts and oven must be brought up to temperature at the same time. This will create a uniform shrink around the part. Convection ovens are also recommended in order to eliminate hot spots which could cause material to shrink unevenly.

- Easier to shrink than PTFE Tubing

- Chemically inert

- Low coefficient of friction

- Flame Rating : VO Self extinguishing

- Biocompatable USP Class VI Certified

- Low gas and vapor permeability

- Gamma and Autoclave Sterilizable