Tef - Cap Industries Inc.

- Home

- Companies

- Tef - Cap Industries Inc.

- Products

- Tef Cap's - Model PTFE 2:1 - Heat ...

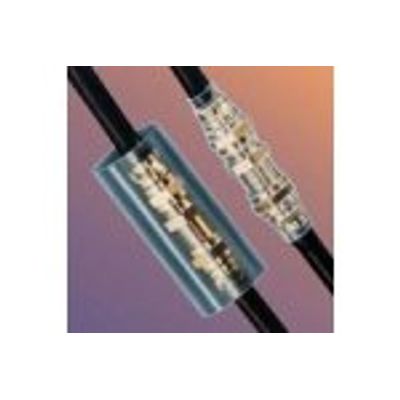

Tef Cap's - Model PTFE 2:1 -Heat Shrink PTFE Tubing

PTFE 2:1 Heat Shrink Tubing possess excellent characteristics for use in high temperature applications, corrosive environments and as an electrical insulator. PTFE Tubing has the lowest coefficient of friction among the Fluoropolymer which makes it ideal for applications that need a lubricious slippery material to reduce linear friction. PTFE Heat Shrink Tubing is chemically resistant to all common acids and solvents making it almost 100 % chemically inert. PTFE Tubing has a high dielectric strength over a wide range of temperatures which is why it is an excellent electrical insulator in corrosive environments and high temperature applications.Most popular related searches

heat shrink tubing

PTFE tubing

coefficient of friction

flame resistant

PTFE standard tubing

friction reducer

AWG Heat Shrinkable material is available in three different wall thicknesses just like Extruded PTFE Tubing. Standard Wall , Thin Wall and Light Wall.

PTFE resins carry a Flame Resistant Rating of UL94 VO and WV-1 which make it ideal for insulating, terminating, moisture sealing, splicing, wire bundling and electrical applications. Although Heat Shrinkable PTFE Tubing does not carry the same UL rating it still complies with a VO rating for flame resistance. Tef Cap can also manufacture Heat Shrink PTFE Tubing for applications where wires or instrumentation needs to be colored coded for identification purposes.

PTFE 2:1 Heat Shrink Tubing offers the ultimate performance with the highest continuous working temperature of all Fluoropolymers.

- PTFE possesses the lowest coefficient of friction of all Polymers.

- PTFE is a non-wetting, self-lubricating material.

- PTFE tubing can be sterilized chemically and is auto-clavable.

- PTFE Heat Shrink Tubing is made to M23053/12

- USP Class VI & FDA compliant