Douglas Electrical Components - Model CircuitSeal -Hermetic Circuit Assemblies

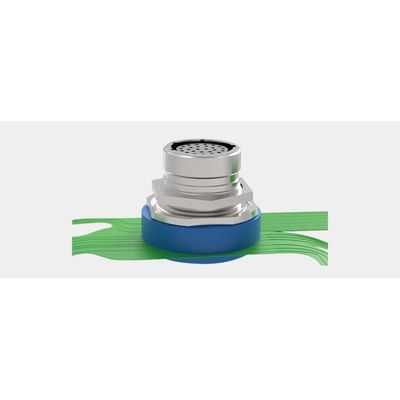

CircuitSeal is the process of hermetically sealing and encapsulating connectors and electronic circuits within a low-outgassing, chemically inert hermetic epoxy. By encapsulating the circuit board, connector, or flex circuit, customers have increased design flexibility to design a small, lightweight electronic package. CircuitSeal can integrate a variety of circuit board and electrical connection types including flex, rigid, hybrid and flat flex cable (FFC). Circuit board encapsulation protects against corrosion and electrical shorts caused by water vapor and condensation or creates a hermetic barrier between the circuit and housing assembly or enclosure.

Non-hermetic connectors offer more design options and are lower cost than their hermetic counterparts. Douglas Electrical can hermetically seal a non-hermetic connector and directly integrate it into the circuit board or flex circuit offering a moisture tight seal as well as connector headers and receptacles. CircuitSeal hermetic packages create cost-effective solutions be enabling customers to use smaller mechanical packages to protect electronics. The mechanical interface can also be customized to simply sit on a hermetic circuit or integrate a housing such as a radial O-ring, jamnut, or bulkhead housing. This adds design flexibility to not only seal the circuit but the mechanical interface that the circuit is designed within including control boxes, housings, and custom assemblies. Our epoxy and the mechanical assemblies can be designed for both vacuum and positive pressure and a wide temperature range.

Hermetically sealed circuit boards are useful for enclosure projects with complex computations as well as sensors, switches, diodes, and capacitors. Potting and sealing effectively blocks and seals against contamination due to outgassing. This hermetic seal technology is also trusted in flexible circuit board connectors and their applications along with hermetic bulkhead applications that require lightweight, compact sealing methods for feedthroughs like missiles, bomb fuses, or even batteries.

Douglas’ hermetic epoxy is certified in various hazardous location designs including explosion-proof, ATEX, and IECEx rated devices, controls, instruments, and more. Partner with Douglas Electrical to encapsulate a circuit designed for hazardous locations.

Common Hermetic Connection Types

- Flat Flex Cable (FFC)

- Printed Circuit Board (PCB / PCBA)

- Pogo Pin Feedthroughs

- Terminal Headers

- Connector Back-potting

- Hybrid / combination designs

Market Capabilities

- ISO 9001:2015

- ISO 14001:2015

- RoHS / REACH compliance

- ITAR DDTC Registration

- Meet various sealing standards and testing methods within MIL-STD-883 MIL-STD-750

- Hermetically seal circuits, sensing elements, fuses, and filters in a compact, chemically inert package

- Improved mechanical and electrical performance and reliability while reducing connection points

- Integrate any of our electrical connection types including MIL-spec connectors to create a hermetic assembly

- Use the design you have or start over – Douglas will partner with you to hermetically seal the circuit within the existing layout or partner to find a better alternative

- Protect against water vapor, condensation, and contaminants

- Low profile assembly

- Meets various MIL-spec standards for moisture resistance

- Chemically inert epoxy

- Hermetically seals to various materials

- Increase conductor density through the hermetic seal

- Design for harsh environments and hazardous locations

- Flex, rigid, hybrid and flat flex cable (FFC) styles

- Suitable for applications with space or weight constraints

- Allows for easy use of active and passive signal conditioning at the glove box bulkhead