- Home

- Companies

- Foshan Luomei Electric Technik Co., ...

- Products

- LUOMEI - Model 100mm - High Pressure ...

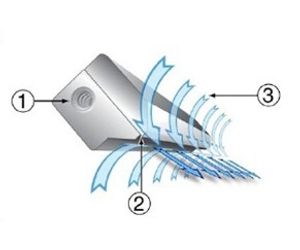

Working principle of super air knife:

The compressed air enters the high-pressure chamber of the air knife through the air inlet (1), and the air flows through the narrow and thin nozzle (2) to form a balanced air flow sheet in the length direction of the air knife. Since the compression ratio of the chamber (3) to the high-pressure air flow is 35:1, the compressed air enters the air knife and is blown out at a high speed with an air flow sheet with a thickness of only 0.05 mm. According to the principle of Konda effect and the special geometry of the wind blade, the thin sheet wind curtain can reach 30-40 times of the ambient air, forming a thin high-intensity, large airflow impact wind curtain.

Advantages of super wind blade:

1. The air enhancement rate is as high as 40:1

2. The product has no moving parts and no electricity

3. Compact structure, light weight and easy installation

4. Low noise - only 70 dB in most cases

5. No maintenance, not easy to damage, long service life

6. The air flow is balanced, adjustable, greatly saving compressed air, and can be turned on / off immediately

7. Aluminum alloy material, stainless steel material can be customized (can withstand 427 ° C high temperature, suitable for corrosive occasions)

8. The length of air knife of various specifications (2 "in-40" in) can be customized

Super air knife application:

super air knife produces powerful air curtain, which can be used for drying of various blowing and air cooling application parts after cleaning process, such as:

1) Electronics industry: electronic circuit boards are quickly dried before assembly.

2) Chemical industry: before labeling or packaging, blow off the surface chemicals or moisture.

3) Rubber and plastic industry: blow away the dust or debris on the surface of products. Dry before ejection or ejection. Cooling after injection molding.

4) Food and medicine: before manufacturing or packaging, blow off the moisture and attachments, or remove the dust from the opening and bag before bagging.

5) Beverage canning and bottle making: before labeling, inkjet or packaging, blow off the water and attachments from the bottle mouth or bottle body.

6) Automotive Industry: used to blow off extra water, coolant, dust, debris, etc. in manufacturing, as well as air cooling, drying and dedusting before painting steel plate.

7) Metal industry: blowing coolant or other liquid from metal surface. Dry or cool the surface before polishing, electroplating and painting.

8) Printing (inkjet): inkjet, pre printing dust, debris, water vapor blowing, or used in ink fast drying, paper and printing industry coater

9) Cleaning of conveyor belt, plate cleaning of belt mill, air curtain cleaning of refuge chamber and refuge chamber