- Home

- Companies

- Shanghai Beyond Machinery

- Products

- Beyond - Model GJJ series - ...

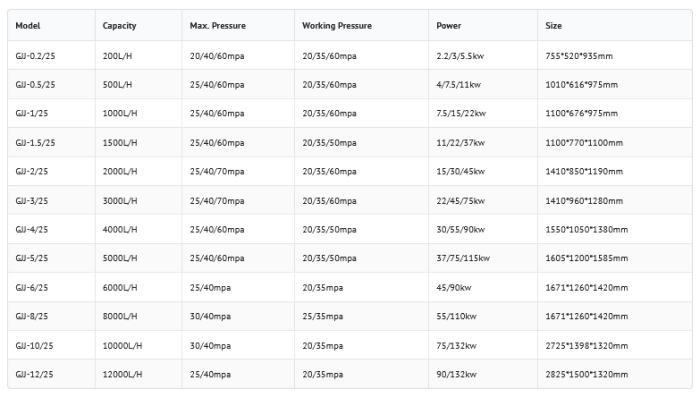

Beyond - Model GJJ series -High-Pressure Homogenizer

The high-pressure homogenizer has been widely used in milk and dairy, fruit juice beverages and sauce, chemical and pharmaceutical industries, fine chemicals in the biochemical industry, and ultrafine crushing to obtain more high-quality products.

For dairy products: it can significantly refine the fat balls in milk, soy milk, yogurt, and other dairy Liquids, make the finished food easier to digest and absorb, improve the taste and extend the shelf life.

For fruit juice: it can prevent or reduce the stratification of the material liquid, improve the appearance of the material liquid, make its color more vivid, the aroma is thicker, the taste is more mellow, extend the shelf life and reduce production costs.

GJJ series high-pressure homogenizer is used to homogenize and emulsify Liquid materials (liquid-Liquid phase or liquid-solid phase) with a viscosity lower than 0.2Pa.s and temperature lower than 80°C

The working principle is that processed material will be sent to the homogenization valve in the form of high pressure through the reciprocating motion of the three plungers so that the instantaneous flow of material through the small gap between the valve disc and the valve seat is subject to turbulence, cavitation, shear With the effect of cutting and other compound forces, the original rough emulsion or suspension is processed into a very fine, uniform and stable liquid-liquid mixed emulsion or liquid-solid dispersion.

Its average emulsification fineness is below lum, solid the dispersed particle size below 2um on average. After the material is homogenized by a high-pressure homogenizer, it has many advantages: it has extremely high stability, can improve storage quality, speed up reaction time, and save additives; it can be used in food, health care products, cosmetics and other fields to improve the absorption quality of the human body.

- The whole machine is covered with a stainless steel shell, and the appearance is smooth and exquisite, safe and hygienic.

- Adopt helical gear low-speed transmission, low noise, stable operation and reliable performance.

- The transmission part adopts splash type and unique oil delivery method to ensure the lubrication needs of each part.

- The double-sided design of the valve seat can double the service life.

- Homogeneous valve, one-way valve and plunger are made of alloy steel, which has the characteristics of wear resistance, impact

- resistance and long service life.