Envex - High Pressure Single Fluid Dust Suppression Systems

The system decomposes and atomizes the high pressure water coming into the single fluid nozzles and turns it into 5-50 micron water fog. Except for the high pressure pump, there is no need for air compressor, control panel, hydrophore and separate hose lines for air-water supply to obtain water fog. In the single fluid dust suppression system, the water coming from the high pressure pump (40-45 bar / 580-650 psi) rotates at high speed with the help of the moving helix part inside the nozzle and compresses at the nozzle outlet and separates into micro-sized particles and becomes water fog. The helix part that allows the water in the nozzle to rotate at a high speed also prevents 50% automatic cleaning inside the nozzle and prevents the nozzle from clogging.

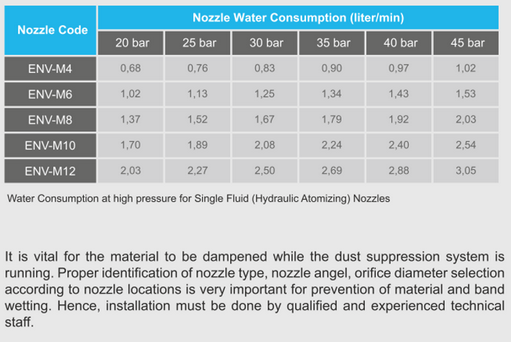

HYDRAULIC ATOMIZING NOZZLES

Single fluid atomizer nozzles atomize water into 5-30 microns water fog. Water supply from the high pressure pump (40-45 bars/580-650 psi) is forced to turn at high speed moving the spiral part of the nozzles. This causes water to atomize form a water fog. Hydraulic atomizer nozzles are produced in different forms according to different use and purposes. Helical parts are assembled, and fixed assembled parts are the types most commonly used. Helical assembled parts also provide 50% auto -matic cleaning in the nozzle via turning in the nozzle.

Fine spray atomizing nozzles are used in the pressurized liquid alone to produce very finely atomized droplets in a hollow cone spray pattern with uniform distribution often achieving misting performance.

Orifice inserts, cores and strainers are easily removed for inspection or cleaning. EN VEX Hydraulic Atomizer Nozzle Series have removable core for easy cleaning or replacement