- Home

- Companies

- Pennwalt Ltd.

- Products

- Pennwalt - High Speed Tubular Bowl ...

Pennwalt - High Speed Tubular Bowl Super Centrifuge

The Super centrifuge is a vertical high speed tubular bowl centrifuge, generating centrifugal force up to 20000 times the force of gravity. It is used either for continuous separation of two immiscible liquids having different specific gravities or for batch-wise clarification / polishing of liquids containing fine insoluble solids.

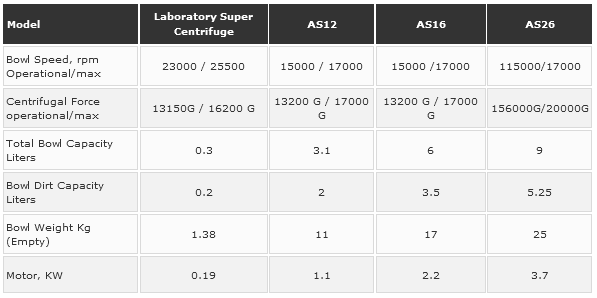

Pennwalt Ltd. are manufacturers of high-G Tubular bowl Centrifuges model AS12, AS16 and AS26 based on the technology acquired from Sharples Stokes Division Pennwalt Corporation-USA.

Pennwalt also supply spare parts manufactured to international standards that are interchangeable on each of the above models of the high-G Tubular Bowl Super Centrifuge

How super centrifuge works

This sectional view of a Super-Centrifuge shows the application of centrifugal force to a mixture of two immiscible liquids containing some suspended solids.

The mixture continuously enters the Super-Centrifuge through an inlet feed nozzle at the base of the machine, into the hollow cylindrical rotor. Rotors have been designed and engineered to rotate at 17000 r.p.m. and generate centrifugal force of upto 20000 times the force of gravity.

This force separates the two liquids according to their specific gravities into concentric cylindrical layers, and the solids are deposited inside the rotating bowl against the rotor wall.

The separated liquids are continuously displaced upwards by the incoming mixture and continuously discharged through their respective outlet ports at the top of the rotor. The layer of accumulated solids that builds up on the inner diameter of the rotor wall is cleaned out batch-wise for which the super-centrifuge is shut down when it is filled up to the rotating bowl’s limiting solids holding capacity and the rotating bowl is removed for cleaning.

There are, however, many applications where only the removal of suspended solids from a single liquid is required. Super centrifuges for such applications are called Clarifiers and are often provided with only one set of discharge ports. Mylar Liners are optionally supplied and can be placed on the inner diameter of the bowl for ease of removal of insoluble solids deposited on the inner diameter of the bowl.

The fields of application of the Super-Centrifuge are almost unlimited. The number of processes which involve a liquid / liquid, liquid / liquid / solid, or liquid / solid separational steps are too numerous to be described here. A few of the better known ones are mentioned briefly below:

General applications here includes Clarifications of

- Dry Cleaner`s Spirit

- Animal Fats Dehydration

- Water Gas Tar

- Fish Oils

- Ball Pen Ink

- Wool Grease

- Printing Ink, etc.

Chemicals and Pharmaceuticals Applications here include:

- Clarification of caustic in Rayon Industry (Steep press liquor)

- Soda solution

- Gum clarification

- Blood fractionation

- Virus recovery

Food Manufacture

- Cider and wine clarification

- Soup clarification

- Fat clarification

- Fruit juice clarification

- Cocoa butter clarification

- Chocolate scrap recovery

- Chewing Gum

- Cherry Syrup

Paint and Varnish

- Removal of oversize pigments from paints and lacquers.

- Clarification of Varnish

- Removal waste ink from newspaper

- Purification of molten wax:

- Removal of ash & water from molten wax in investment casting industries.

For Bio-diesel Production

The model AS-16 and model AS-26 high-G Tubular Bowl Super Centrifuge are used for the following separations in Bio-diesel Production to obtain the final purity of Bio diesel to international standards eg. ASTMD-6751:

- Machine can be operated at high G forces up to 20000 x G

- Centrifuge enclosure can be designed for N2-blanketting & minimum solvent vapors loss wherever excess methanol is present.

Features :

- Separation of Biodiesel from Glycerol+Methanol mixture after trans-esterification.

- Separation of Biodiesel from Wash-Water in the subsequent bio-diesel washing steps.

The machines can be supplied whenever required, with special features for minimizing solvent loss and for mitigating solvent hazards.