- Home

- Companies

- Process Engineering Srl

- Products

- Jet-Helix - Model JH - High Yield Air ...

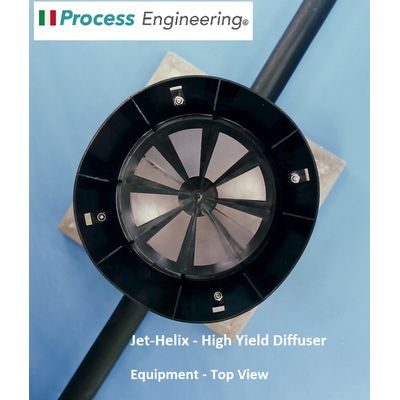

Jet-Helix - Model JH -High Yield Air Bubble Diffuser

Thanks to the expertise and knowledge acquired in the utilization of HelixoR for the engineering and realization of waste water treatment plants, during the 80’s Dr Petrillo started to think-up and develop a new equipment. This New Air Bubble Diffuser had to have the following properties: > an oxygen transfer, higher than the HelixoR > high mechanical resistance > high efficiency > long working life > resistance to chemical The result of these R&D, calculations and design activities is the invention by Eng Giacinto Petrillo of the Jet-Helix® Patents and trade-marks have been deposited Nowadays the Jet-Helix, that is a Turbulent Mixing Fine Air Bubble Diffuser, is thte Aerator Staic DIffuser with the Highest Oxygen Transfer Capacity available in the Market.The Jet-Helix can have different heights in function of the number of elements that constitute the tube.

In particular we manufacture the following equipment:

- the 2 ELEMENT Jet-Helix - i.e. the equipment with a 0.90 meter high

- the 3 ELEMENT Jet-Helix - i.e. the equipment with a 1.20 meter high

- the 4 ELEMENT Jet-Helix - i.e. the equipment with a 1.50 meter high

In the most of the applications , the following equipments are mainly used:

- 3 Element Jet-Helix Diffuser

- 4 Element Jet-Helix Diffuser

The choice of the equipment to be used is done in function of the following parameters:

- water/liquid depth in the aeration basin

- oxygen required by the application (BOD and COD)

- quantity and type of suspended solids (SSM)

The relevant curves for the Oxygen Transfer Capacity give the capacity of the Jet-Helix equipment to dissolve the oxygen in the water of a basin, where the aeration is performed through the compressed air pumped into the Jet-Helix equipment.

The curves report the experimental data obtained in the tests and give the values for the Transferred Oxygen.

The obtained results - i.e. the transferred oxygen - are measured in : Kg O2 / h / Jet-Helix.

- The Oxygen Transfer Curves have been obtained with experimental tests done to measure the Dissolved Oxygen.

- These test have been done using a proper pilot plant equipped with all the required apparatuses such as

- measurement equipment

- blowers

- that have made possible the experimental obtaining of the Oxygen Transfer Curves in function of the following variables

- the water depths

- the blown air flow

- the type of Jet-Helix diffuser installed.

Further to the experimental activity related with the Oxygen Curves of the Jet-Helix, the pilot plant has been used for `On Site Experimentation`.

When the a b coefficients or other process parameters were unknown or when it has been necessary to have experimental data regarding the wastes of the Client Plant, the use of the pilot plant has been applied to experimentally obtain the required parameters.

This procedure and the test service allowed to perform a proper scale and an "ad hoc design" of the waste water treatment plant requested by the Client.

Thanks to their Transfer Capacity, the Jet-Helix - High Yield Medium-Fine Air Bubble Diffusers - are successfully applied for the Aerobic Treatment of Waste Waters, either for:

- Civil & Domestic Wastes

- Industrial Wastes

- Mixed

- `Special ` Wastes

In the various range of their application, we underline:

- Pharmaceutical Industry

- Chemical-Pharmaceutical Industry

- Oil & Gas

- Chemical & Paper Industry

- Mechanical & Automotive Industry

- Rubber & Latex Industry

- Petrochemical Industry

- Rubber Thread Industry

- Refineries

- Oils & Metal Recovery Industries

Up to now, more than 5.200 Jet-Helix Aerators have been successfully supplied all-round the world by our Team & Organization.

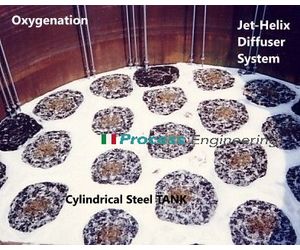

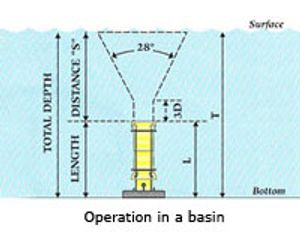

- The Jet-Helix is positioned on the bottom of the Aeration Tank/Basin.

- The positioning is properly done so to have the optimization of his operation when running.

- Thanks to its geometrical characteristics and to the presence of fluid-dynamics appendages (top and bottom section), the Jet-Helix guarantees the formation of an appropriate functioning cone area.

The entity of such a cone depends on physical parameters (liquid height, equipment height, free net distance) that defines:

- the pumping capacity and flow

- the motion and the recirculation of the liquids from bottom to top

- the recycle through spiral movement of the waters all around each Jet-Helix

In addition to the high oxygen transfer capacity as reported by the Oxygen Curves , the Jet-Helix Diffuser has also the function to pump the liquids.

The Hydraulic Pumping Capacity depends on the diffuser height .

This further property of the Jet-Helix enables to obtain

- the recirculation

- the mixing

- the agitation

of the waters inside the basin so evoiding

- the deposit of the solids

- the formation of “calm zones” in the aeration tanks.

The Total Hydraulic Delivery to Surface per Jet-Helix Q T= m3/day/Jet-Helix depends by the following factors

- Q L Total Delivery throughout the Jet-Helix

- S free net distance over the Jet-Helix

- the Jet-Helix Diameter

The total flow rate QT depends on the air blown through the Jet-Helix.

The data here reported were obtained with an air flow equal to 22 scfm.

- The Jet-Helix diffusser is built only by PE using Proper Procedures and High Quality Materials.

- For this Application, we use the following MATERIALS:

- Brackets = made in SS AISI

- Packing = HDPP

- Parts = other Eqipment Parts in HDPP

- Hereby we report the of the Jet-Helixor we design, build and supply.

- The Main Technical Properties are reported .

Expertise: More than 5500 pieces More than 260 Plants

- The Jet-Helix is the Best Equipment for the Waste Water Treatment Plants W.W.T.P. so far so that till today :

- More Than 5,500 Pieces have been built and supplied

- More Than 260 Plants have been realized and commissioned since its patents.