- Home

- Companies

- Wellspring Co., Ltd.

- Products

- MEMS - Hollow Fiber Membrane (HFM) ...

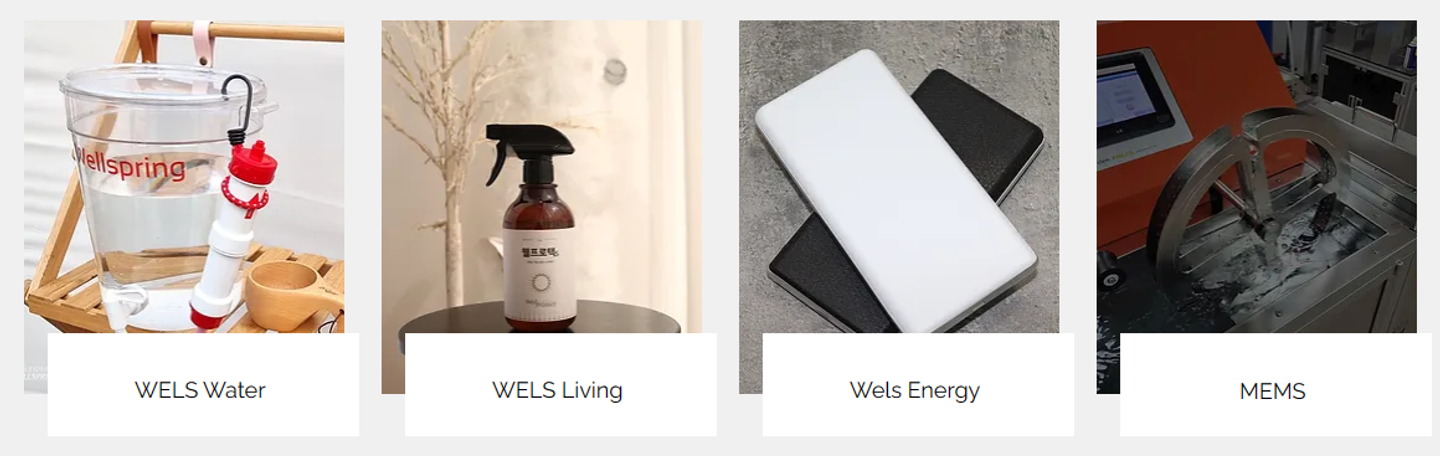

MEMS - Hollow Fiber Membrane (HFM) Manufacturing System

MEMS offers a diverse range of facilities involved with hollow fiber membrane production. It comprises facilities to spin fibers, fabricate modules, and evaluate hollow fiber membranes. MEMS has it all, from basic experimental devices to industrial facilities. Hollow fiber spinning, potting, cutting, and coating systems are all available from MEMS in a variety of standard configurations. However, it is also possible to tailor the systems to the needs of the customer. Customers may spin single- or double-layer hollow fibers using the MEMS spinning system. Moreover, MEMS potting system also has the ability to pot up to 48 modules at a time. The systems are compact and easy to use since they were built by researchers to assist reduce the time and effort required to do the tasks.

We have a long history of membrane research, manufacture, and engineering, and we know exactly what goes on in the lab. We have a greater understanding of the difficulties you face as researchers than anybody else, and we`re here to help. While working with researchers, we have studied each of them attentively and attempted to comprehend the psychology of researchers. When doing research, we know that ease of use is the most important factor.

We have witnessed that, despite possessing pricey and properly functioning equipment, many researchers nonetheless employ poorly constructed equipment just because they are more comfortable to use. Most of the times, the pricier the system the more complicated it is and the more room it takes in the lab, while needing a lot of cleaning, and are not even suitable for acquiring desired results. As a result, we at MEMS have made it our duty to supply researchers and developers of membranes with the most user-friendly and convenient equipment. In order to overcome even the smallest obstacles, MEMS was established. So, at MEMS, we offer "A device that understands the researcher`s mind" by adapting to the user mind of researchers via our years of expertise, observation, and realization. That`s what we`d want to put forward to the community of researchers.

Recognizing the user`s mind of research, we at MEMS offer the most precise, user-friendly, time and space efficient hollow fiber membrane manufacturing system. MEMS hollow fiber membrane manufacturing equipment allows researchers to not only prepare a lot of membrane samples in a short time with confidence in reproducibility and accuracy but can also permits to carry out experiments in various conditions.

MEMS makes the experiment easy as it solves one of the most concerned issue of researchers; Cleaning. Especially considering the challenges of cleaning the dope tank, we have designed MEMS hollow fiber spinning system is such a way that researchers no more have to worry about cleaning. We have adopted the use of disposable plastic bottles in the dope tank which can be changed every time a user wishes to work with new ingredient. This simple yet important and innovative design can save user much time and energy by making the whole experimenting experience more likeable.

Moreover, with MEMS users can now put them self at ease and not worry much about that little extra space they might need in their lab to adjust a new equipment. MEMS`s compact designs make it more adjustable to fit even in the smallest of space as it has been constantly working with experts and design engineers to make the system more compact, skilled & precise.

Researchers will certainly benefit with reliable and accurate results from MEMS hollow fiber manufacturing machine as it is equipped with various sizes of spinnerets, gear pumps, inverter control, and other control systems with the highest precision allowing researchers a great precision control for the overall process from start to finish; spinning to winding. Perhaps this might even help the researcher collect more data.

In addition to obtain good and reproducible result, our experts suggest a separate water bath to be installed in the device which will completely remove solvents and additives from the membrane. As without this process, it is never possible to create a membrane with good performance and no reproducibility can be obtained.

MEMS will help you to get more reliable and diverse data.

The process of hollow fiber membrane manufacturing

MEMS supplies all sorts of facilities associated with the membrane manufacturing from the materials used to the technical facilities, it provides an overall solution to membrane manufacturing. Even the facilities to manufacture modules, and to evaluate them are available at MEMS. Including very simple experimental devices to production facilities, MEMS has it all.