- Home

- Companies

- Harmony Enterprises, Inc.

- Products

- Harmony ExtractPack - Model Max - ...

Harmony ExtractPack - Model Max -Horizontal Liquid Extraction Baler

The largest of our liquid extraction balers, the ExtractPack Max, is on the cutting edge of extraction and baling equipment! The ExtractPack Max offers even greater functionality with the same broad range of baling and extracting options as the ExtractPack Plus (PERF-SSHB Gen 1), including a mill-sized bale!

- Bale Size: 45"L x 42"Wx 30"H

- Bale Wt. (Alum): 765 lbs.

- Bale Wt. (PET): 875 lbs.

- Top Of Line Beverage Baler

By using our large horizontal liquid extraction baler, not only are you keeping material out of the waste stream, you are creating a new revenue stream for your business!

The increased bale weight capacity and ability to generate a mill-sized bale makes this product extremely desirable for companies that want to improve their recycling revenue. Production facilities have realized an ROI of one year with a combined recycled revenue and an approximate savings of a 1.5 FTE. Instead of using only 4500 aluminum cans to make its bale, the GEN2 uses over 25,000 aluminum cans in its bale making process!

The Harmony ExtractPack Max is a large horizontal liquid extraction baler that perforates, de-liquifies, and bales large quantities of aluminum, plastic, paper or corrugated containers. The easy to clean liquid reservoir and filter system located on the rear of the machine ensures a clean, safe, and user friendly method for liquid extraction. The entire machine can be washed down after use and resists corrosion.

Used often as a bottling facility baler or a brewery baler, Harmony Enterprises will custom build your ExtractPack Max to your exact specifications and needs. Let our professional sales team lead view through a no-obligation site review and needs assessment to ensure that you are getting exactly the right solution for your particular operation.

- Creates a standard mill-sized bale

- Heavy duty stainless steel baling chamber, platen and charge opening

- 207-gallon stainless steel liquid reservoir assembly with custom 2PC straining screen system to catch debris.

- Custom designed stainless steel splash guards, safety covers, and power unit weather cover that have a peaked design to allow for liquid run off.

- All electrical enclosures are stainless steel NEMA 4 rated and all fittings and conduit are non-corrosive plastic water tight rated.

- All electrical items are OEM off-the-shelf by design so not waiting around for special orders on replacement items if needed.

- Allen Bradley PLC & HMI.

- Water proof ultrasonic sensors to monitor charge chamber filling and cycle start operations. No troublesome photo eyes to clean or service.

- Water proof magnetically coded safety switches to monitor all gates and doors.

- Water proof proximity switches to monitor ram locations. No limits switch arms or rollers to keep readjusting.

- Comes standard with CAT 3 electrical and hydraulic safety circuits.

SPECIFICATIONS:

- Baler Weight: 25,600 lbs (11,612 kg)

- Tipper Weight: 3,400 lbs (1,542 kg)

- Platen Total Force: 235,600 lbs (106,866 kg)

- Platen Penetration: 100%

- Platen Cycle Time: 45 seconds

- System Pressure (main): 3,000 psi

- System Pressure (secondary): 2,500 psi

- Pump (main): 46 GPM Variable Piston

- Hydraulic Circuit (main): Regenerative

- Hydraulic Circuit (secondary): Standard

- Oil Reservoir Volume: 110 gallons

- Platen Cylinder: 10″ bore x 6″ rod x 75″ stroke (25 cm x 15 cm x 191 cm)

- Latch Cylinder: 4.5″ bore x 2.5″ rod x 7″ stroke (11.4 cm x 5 cm x 17.8 cm)

- Door Cylinder: 4.5″ bore x 2.5″ rod x 10.5″ stroke (11.4 cm x 5 cm x 25.4 cm)

- Tipper Cylinder: 3″ bore x 1.5″ rod x 20″ stroke (7.6 cm x 12.7 cm x 50.8 cm)

- Tri-Volt Electrical System: 208/230, 460, 24VDC, 3HP, 25 HP

- AutoLube Grease System: 2 Liter

- Oil Cooler: 1/2 HP

DIMENSIONS

- Bale Dimensions: 45″L x 42″W x 30″H (114 cm x 106 cm x 76 cm)

- Estimated Bale Weights: Aluminum: 765 lbs (347 kg) / PET: 875 lbs (397 kg)

- Bale Volume: 35 cu. ft. (.99 cu. m)

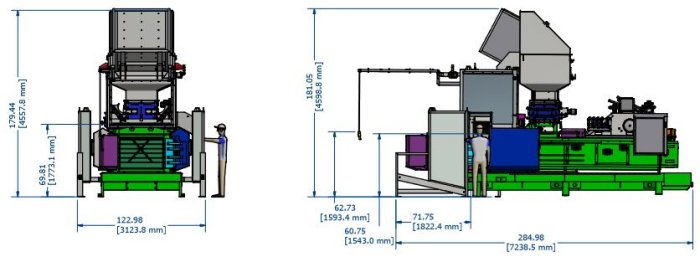

- Baler Dimensions: 224” L X 92” W X 177″ H (569 cm x 234 cm x 450 cm)

- Baler Operating Area: 270” L X 128” W X 177″ H (686 cm x 325 cm x 450 cm)

- Tipper Dimensions: 117” L X 123”W X 144”H (297 cm x 312 cm x 366 cm)

- Tipper Operating Area: 203″L X 142″W X 177″H (516 cm x 361 cm x 450 cm)