- Home

- Companies

- Komline-Sanderson

- Products

- Komline-Sanderson - Model CIX - ...

Komline-Sanderson - Model CIX -Horizontal Vacuum Filters

The K-S CIX Horizontal Vacuum Filter is a top fed filter that can perform filtration, extraction, and drying in one machine. Slurry is fed continuously and forms a filter cake, which can then be washed as it is progressively indexed through discrete zones. Slurry is fed continuously and forms a filter cake, which can then be washed as it is progressively indexed through discrete zones. It is ideal for applications requiring counter current washing and precise separations.

Features of the CIX include:

- Continuous Indexing Filter

- Excellent Cake Washing

- Filter Dense Materials

- Superior Process Flexibility

The Komline-Sanderson CIX Horizontal Vacuum Filter is typically used for the filtration of crystalline slurries and washing of the filter cake. Some end uses are:

- Pharmaceuticals

- Fine Chemicals

- Gypsum

- Zeolytes

- Mineral Concentrates

- Pigments/Dyestuffs

- Pulp and Vegetable Matter

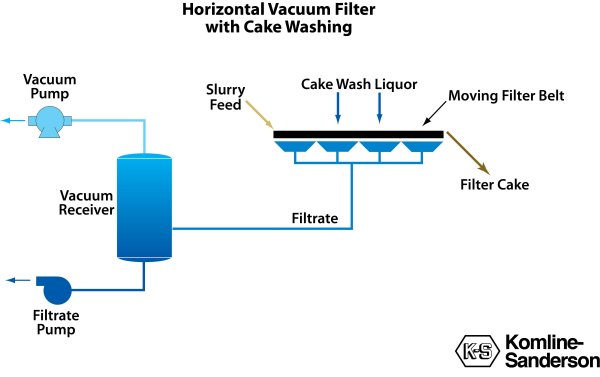

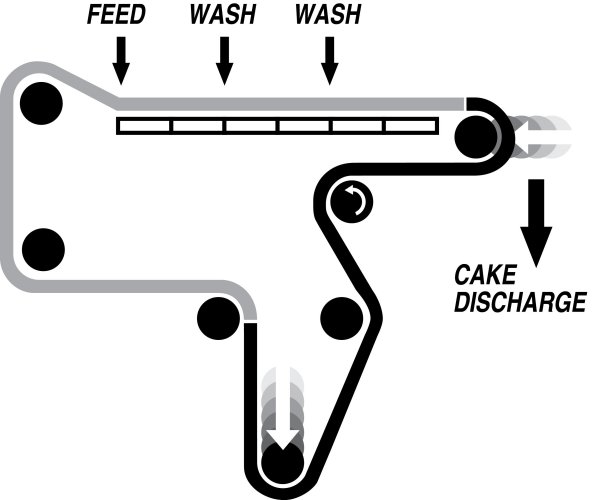

The process of the HVF is continuous. The filter cloth moves forward through cake formation, cake washing, dewatering or drying, and cake discharge.

- Feed slurry is deposited continuously onto the cloth.

- Vacuum draws liquid through the filter medium (cloth) which retains the solids.

- The vacuum pulls air (or gas) through the cake and continues to remove moisture as the cloth moves forward.

- The filter cake can be washed in multiple stages to remove impurities or to extract more product. Additional drying of the cake follows washing.

- Finally, the cake is discharged from the drum to a conveyor or chute to the next process step.

- The filtrate and air are pulled through the medium flow through filtrate pipes and pass through a control valve and into the filtrate receiver.

- The liquid stream is separated from the vapor stream in each receiver.

- Liquid filtrate is then pumped to the next step in the process.

- Vacuum is applied using a liquid ring vacuum pump or other means.

How do I know if a Komline-Sanderson HVF is right for my process?

Does your process involve:

- Continuous separation of solid and liquid

- Solid or Liquid Product recovery

- Cake washing for cake purity or liquid product extraction

Are you interested in:

- Minimal operator attention

- Low maintenance time and expense

- A well-built machine offering long equipment life

If you can relate to these objectives, then follow these steps:

- Establish process inlet and outlet conditions as accurately as possible

- Complete the K-S Applications Questionnaire

- Contact us to assist in making a preliminary selection

- Perform lab and/or pilot scale testing if necessary

- Make final selection

Other considerations:

- What is immediately upstream and downstream of the filter?

- What is most important: cake solids, filtrate clarity, capital or operating cost, etc.?

- What have you tried before? Why did/didn`t it work?

- What materials of construction are acceptable? What are not?

- Do you need auxiliary equipment?

- Do you need any instrumentation or controls?

- Do you have any standard specifications?

There are many factors affecting the operation of a filtration process. Among these are power, water, air, or other utilities; operator attention; cleaning requirements; and maintenance needs. All of these should be considered when selecting a filter.

- Continuous operation

- Application versatility

- Ease of operation, requiring minimal attention

- Simple, durable design for low maintenance and long life

- Wide Range of Sizes

The benefit of the CIX filter is what happens between the continuous feed and continuous discharge.

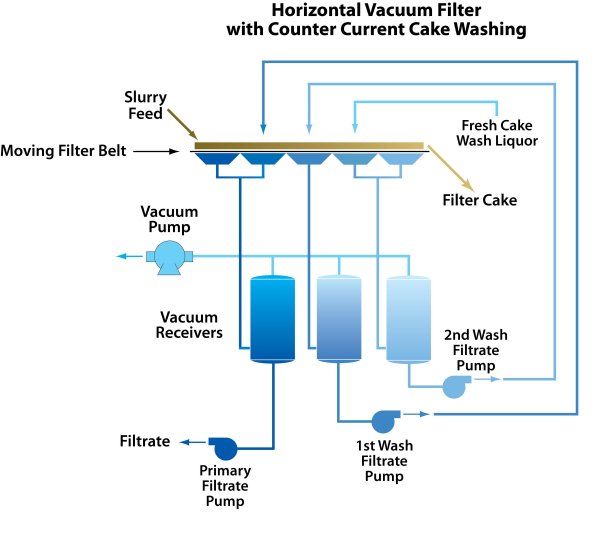

The filter tray can be divided into zones to suit your flow sheet. The filtrate from one process zone can be isolated from that of the adjacent zone making the filter an excellent choice for counter-current washing.

The filtrate pipes from each zone or group of zones terminate at a control valve. The control valves can be programmed to actuate at any point in the cycle providing the operator with extraordinary ability to control cake cracking. Wash liquor can be given some residence time before vacuum is applied to a particular zone.

The stationary filter tray of the CIX filter, with its high sides, ensures there are no spills and the overall cleanliness of operation is exceptional.

How can we help you?Komline-Sanderson has been a leader in liquid/solid separation equipment design and manufacturing for over 60 years, meeting the needs of both industrial and municipal clients. Our filters operate worldwide in an ever-growing range of process and wastewater applications. Expert process insight, outstanding customer service and high quality equipment make K-S a valuable partner throughout the project cycle.

Lab and pilot testing service is available to assist in equipment selection and sizing. Testing is also used to determine cake washing needs or other operating aspects.

Komline CIX filters are usually modified to meet the special requirements of the customer’s process.

The filter tray can be divided into zones to suit your flow sheet. The filtrate from one process zone can be isolated from that of the adjacent zone.

The filtrate pipes from each zone or group of zones terminate at a control valve. The control valves can be programmed to actuate at any point in the cycle providing the operator with extraordinary ability to control cake cracking or to allow wash liquor some residence time in contact with the cake.

Some common material options include:

- SS trays with SS frame

- SS trays with painted steel frame

- Polypropylene trays with painted steel frame

- Polypropylene trays with FRP frame

CIX filters can be supplied with vapor retaining or vapor tight enclosures.

K-S process and project engineers provide assistance at all phases of the project. Depending on your specific requirements, K-S can provide you with a Horizontal Vacuum Filter or a complete system.

A successful plant depends on the integration of the key process units with properly selected ancillary equipment and the right facility design. Reliability, ease of operation, rugged construction, performance, and the superior customer service we offer are all trademarks of a K-S installation.

A typical system includes a vacuum pump, filtrate pump, and vacuum/filtrate receiver. Also required in some cases are feed or cake wash pumps. Often these items are mounted, wired and piped on a common base for ease of installation. Depending on customer needs, cake-handling equipment can also be provided. Controls and instrumentation are available to complete the system.

When necessary, our vapor tight design allows for the processing of material containing organic solvents and hazardous materials in an enclosed safe manner. Inerting of the process with nitrogen can also be accomplished with a minimal purge rate.