AMETEK PI - Model 909 -Hot/Wet Single Gas Mass Flow CEM

The 909 is a single gas continuous emissions monitoring (CEM) system that measures stack effluent temperature and velocity alongside pollutant concentrations at stack conditions. This enables mass emission rates to be reported. With no moving parts, the 909 offers high reliability and reduced maintenance requirements. It provides sample and mass flow measurements in one device, with an optional zirconium oxide sensor for oxygen measurement.

The sample cell and all components in contact with the sample are heated above the dew points of all gases in the sample stream. This gives a more accurate calculation of gas concentrations, compared to CEM systems that require water removal or sample dilution.

Designed specifically for stack emission monitoring in sulfur recovery incinerators and sulfuric acid plants, the 909 is ideal for applications in the hydrocarbon processing industry.

FULL-FUNCTION CEM

The 909 performs all necessary sample gas and calibration flow management tasks, as well as probe and sample line temperature control. Only a sample probe and sample line are required for full operation.

DURABLE DESIGN

Designed to operate without moving parts, the 909 is built for maximum reliability and durability. It is a complete system with a sample extraction and transport system designed to ensure sample integrity.

HIGH-RESOLUTION UV TECHNOLOGY

High-intensity line-source lamps provide a resolution better than 0.02nm, enabling excellent linearity over a wide dynamic range and leading to highly accurate measurements.

The 909 is the single gas mass rate CEM solution for stack emissions monitoring in sulfur recovery applications – Find out more.

Features- Reduced maintenance requirements

- Sample and mass flow measurements in one device

- No water compensation or correction factors needed

- Automated zero and span gas calibrationsE

- High reliability and reduced maintenance requirements through a no-moving-parts-design

- Hot/wet analysis prevents errors associated with:

- Correcting for water vapor

- Absorption losses in driers

- Accuracy better than 2.5 ppm SO2

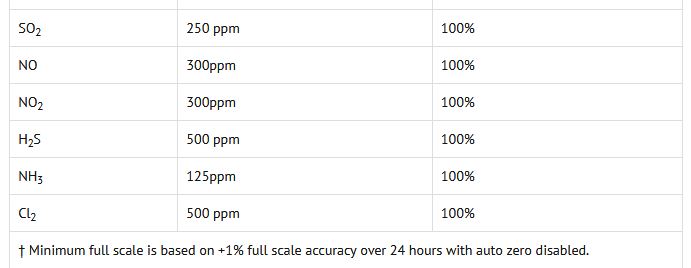

- Able to measure SO2, NO, NO2, H2S, NH3 or a number of other chemicals

- No H2O or CO2 interference

- Automated zero and span gas calibration

- Provides serial interface with plant DCS

- Incorporates flow measurement for emission rate calculations.

Methodology: Dual beam, high resolution, nondispersive UV

- Optional O2: Integral zirconium oxide

- Accuracy: Better than ±1% full scale of standard ranges

- Repeatability: Better than ±0.5% full scale of standard ranges

- Linearity: Better than ±1% of full scale

- Response Time: Typically less than 30 s to T90 (excludes sample system)

- Sample Transport: Air aspiration

- Typical Sample Flow: 3 to 5 L/min (0.1 to 0.2 CFM)

- Temperature Control: Independent control of three zones (oven, sample line, probe)

- Pressure and Temperature Compensation: Standard

- Ambient Temperature*: 5° to 50°C (41° to 122°F)

- Instrument Air: Minimum 413.6 KPa (60 psig), 120 L/min (4.24 CFM), instrument quality air

- Power: 120 VAC °±10%, 47 to 63 Hz or 240 VAC ±10%, 47 to 63 Hz, 600 W for analyzer only

Communications

- Analog: 4 x 4 to 20 mA self powered

- Digital:

- One RS232 port for service diagnostics

- One RS422 with Modbus protocol

- Relays: 3 independent sets of SPDT relays alarm conditions

- Physical Dimensions HxWxD: 1553.6 x 1117.6 x 306 mm (61.17 x 44 x 12 in.)

- Weight: Estimated minimum 160 kg (350 lbs.)

- Approvals and Certifications:

- NEC/CEC Class I, Division 2, Groups C & D

- ATEX II 2G EEx pd IIB T3

- Russian Ex Proof Certification; 1ExpydIIBT3

- Russian Gosstandart Pattern Approval

- Complies with all relevant European Directives

* Temperature drift is approximately 1 ppm/°C for the species listed. To achieve maximum accuracy and stability, the analyzer should be installed in a temperature-controlled environment or be zeroed more frequently.

- NEC/CEC Class I, Division 2, Groups C & D

- ATEX II 2G EEx pd IIB T3

- Russian Ex Proof Certification; 1ExpydIIBT3

- Russian Gosstandart Pattern Approval

- Complies with all relevant European Directives

- Sulfur Plants

- Smelters

- Power Plants

- Industrial Boilers and Process Heaters