- Home

- Companies

- Flame Spray Technologies BV

- Products

- FST - Model Hv-50-Lf/M Mobile - Liquid ...

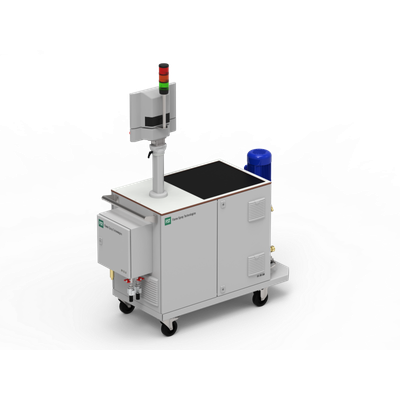

FST - Model Hv-50-Lf/M Mobile - Liquid Fuel -HVOF Coating System

The HV-50M/LF is a stand-alone single process, mass flow controlled (MFC) HVOF coating system. Built using only state-of-the-art components and technologies, the HV-50 is designed to be both reliable and functional and can be used in every type of HVOF application, ranging from R&D, single-piece production to high volume production.The HV-50-LF/M is engineered and built to be the safest HVOF system available on the market today for continuous and consistent coating production. This is achieved by using the latest safety standards such as modular construction, separating gases and fuels from the electrical parts; the use of only first-class materials and closed-loop control of all relevant process parameters such as gas pressures and flows; water temperatures, and gas monitoring. Safety interlock integration and e-stops with external equipment such as cooler, part- and gun manipulation units come standard.

HV-50-LF/M spray guns:

- eGun™

- JP-5000

- Integration of other liquid spray guns on request

HV-50-LF/M Powder Feeders:

- PF-50 Powder Feeder

- FST-10/MC or FST-20/MC

- Integration of other powder feeders on request

Refrigerated Cooling System

FST has the right water cooling solution to safely and correctly operate any Liquid Fuel HVOF system

- Runs on Horizon software:

- FST | Horizon™ operating software

- FST | Horizon™ data reporting on PC

- FST | Horizon™ information centre on PC

- FST | Horizon™ turn-key maintenance scheduler

- System components connected to a single network with digital communication:

- Simatic s7-1500 PLC The process controller is PLC based providing maximum reliability

- No external influence of the signal: Data transfer is based on a 24V signal. Screened cables and required grounding are no longer necessary.

- No measured value losses: The entire measured value transmission is digital. Transmission that is prone to errors and calculation of analogue signals is replaced.

- Easy component replacement: All sensor parameters are stored in the master and transferred to the replaced unit.

- Identification: Only like for like replacement. No wrong sensors accepted.

- Wire break detection/diagnosis: Wire break or short-circuit is immediately detected.

- Master/slave integration via Profinet

- Modular construction enables future expansion of a single-process system to multi-process.

- High Definition 22” Touch Screen HMI provides clear user-friendly access to process control parameters and monitoring functions.

- Closed-loop mass flow controllers for all process gases including carrier gas and ES-flow controllers for all liquid fuels.

- Remote diagnostics minimising the system failure analysing efforts, through the use of eWon technology.

- The HV-50 controls all system peripheral or auxiliary components, such as heat exchangers, dust collectors and so forth.

- All process-related parameters are closed-loop for maximum coating consistency.

- Multiple gun technology; can handle most HVOF spray guns.

- Master control integration and operation of FST powder feeders.

- Fully compliant with all relevant CE and UL directives.

- HV-50-LF

FST Horizon™ professional Thermal Spray Software – operates multiple thermal spray processes in one modular software platform. Increase your production output by using FST’s reliable, versatile, unmatched process control delivered by FST’s 50 Digital Series systems.

- FST | Horizon™ operation software

- FST | Horizon™ data reporting

- FST | Horizon™ maintenance scheduler

- FST | Horizon™ information center