- Home

- Companies

- ResinTech Inc

- Products

- ResinTech - Model BSM-50 - Hybrid Anion ...

ResinTech - Model BSM-50 -Hybrid Anion Exchange Resin Silica & Antimony Selective Borate Form

ResinTech BSM-50 is a borate form hybrid anion resin selective for silica and antimony. BSM-50contains hydrated iron oxide crystals monatomically dispersed throughout the polymer. It absorbs antimony, silica, and other contaminants by a combination of ion exchange and adsorption. ResinTech BSM-50 is intended for removing trace levels of antimony and can also be used to remove silica from borated process waters. BSM-50 is supplied in the borate form.

- Polymer Structure: Styrene/DVB

- Polymer Type: Gel

- Functional Group: Hybrid

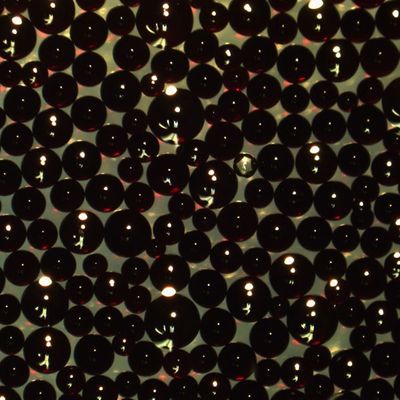

- Physical Form: Spherical Beads

- Ionic Form (as shipped): Borate

- Water Retention: 35 to 50 percent (BO Form)

- Approximate Shipping Weight : 51 lbs/cu.ft. (BO Form)

- Screen Size Distribution : 16 to 50 (U.S. Mesh)

- Maximum Fines Content: 1 percent (less than 50 Mesh)

- Minimum Sphericity: 93 percent

- Uniformity Coefficient: 1.6 (Approximate)

- Resin Color: Black

High Affinity for Antimony and Silica Over Other Anions

Formulated for selective removal of antimony and silica

Supplied in Borated Form

Resin is supplied in the borated ionic form which eliminates any potential release of chloride ions

Superior Physical Stability

93% plus sphericity and high crush strengths together with carefully controlled particle distribution provides long life and low pressure drop

Controlled Particle Size

16 to 50 mesh size provides a low pressure drop and superior kinetics.

Antimony Removal

Trace levels of antimony are adsorbed by the iron hybrid material inside ResinTech BSM-50, which in all other respects remains a strong base anion resin. The resin is typically used as the bottom layer of a multilayer exchange tank. Antimony removal reduction is typically around 90% and in recycle applications where the source of antimony has been removed, remaining antomony can be reduced below the limit of detection.

Silica Removal

ResinTech BSM-50 can be used at moderate pH to remove silica. At a flow rate of 0.5 BV/min, removal efficiency of ninety percent is possible for several hundred bed volumes of throughput. Silica does not dump as the resin exhausts; silica leakage increases gradually but some removal continues for many thousands of additional bed volumes. Even though silica removal is not complete, the lowering of silica helps maintain purity in spent fuel pools and other radwaste systems.

Removal Of Other Trace Contaminants

ResinTech BSM-50 is also able to remove other traces of activated metal oxides such as nickel, tin, and tellurium.