- Home

- Companies

- EMC Hycal Limited

- Products

- Hycal - Model 100 - Portable Advanced ...

Hycal - Model 100 -Portable Advanced Dissolved Hydrogen Analysis System

Probe longevity: 100 measurements typical, 20 hours continuous immersion. Response time: 5 minutes to stable result, response time less than 2 seconds. Operating expense: 3 x lower running cost, reduced degassing cost. Capital expenditure: Less than 50% CapEx, PLC not included.

- Networked

- Reduced

Reduced features. Multiplexed installation.

- 10x life

- 3x faster

- 1/3 OpEx

- 1/2 CapEx

“A cut-down version of the Hycal 1000 for multiplexed installations”

- Lower CapEx

- Integrate with existing PLC / HMI

- Profinet & EtherNet/IP options

- Probe automation

- Longer probe life

- Improved repeatability

- Eliminate operator error

Parameter: Specification

- Unit of measurement: ml/100g [@ 20°C and 1 atm] (milliliter of hydrogen per 100 grams of liquid aluminium)

- Sensor type: Electrochemical. Solid-state reference

- Reproducibility: ±0.01 ml/100g or 3% of hydrogen concentration

- Response time: Initial result: 5 minutes typically. Subsequent response: < 5 seconds

- Temperature of operation: 620°C to 800°C

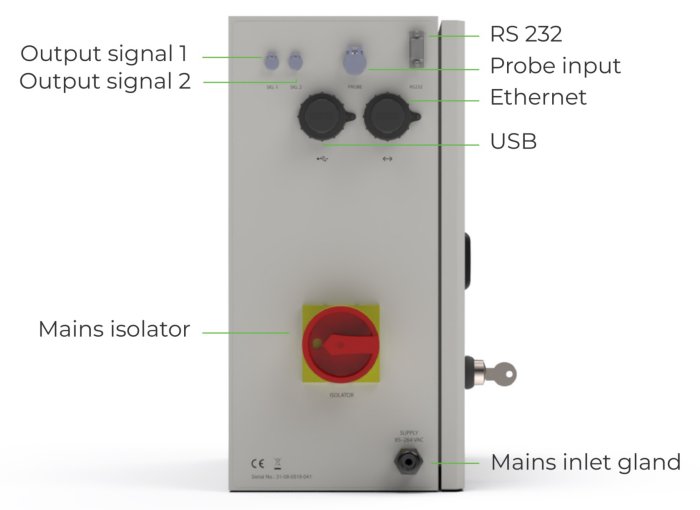

- Analyser: 400(W) x 400 (H) x 200 (D) mm. / 15 kg.

- Probe: Standard length: 800mm.Maximum depth of immersion: 300mm Diameter: 6mm

- Probe cable (std): 3000mm

- Refillable gas bottle (300ml): Dry argon or nitrogen. Max fill pressure: 120 bar

- Thermocouple: Type K

- Specified limits of error: 1.1 deg C or 0.4% - whichever the greater

- Power supply (external unit): AC 85 - 265 V, 47 - 63 Hz

- Typical power consumption: < 10 W (probe heater off, battery discharging)

- Max. power consumption: 210 W (probe heater on, battery charging)

- Ethernet interface: 10/100 Base-T, RJ45

- Communication protocol: MODBUS TCP

- USB: 2.0 full-speed (Type A)

- Operating Temperature: 0 - 60 deg C

- Humidity: 5 - 95% non-condensing

Hycal 100 offers most of the measurement capabilities of the Hycal 1000 i.e.:

- configured gateway

- 2 x signal relay outputs

- I/O customisation options

However, it does not include the following:

- HMI

- Internal gas tank

As such, several of the functions available in the Hycal Mk4 and Hycal 1000 are not available in the Hycal 100.

It is particularly suited to a multi-furnace operation where a multiplexed hydrogen control network is required - such as a low-pressure die casting foundry environment.

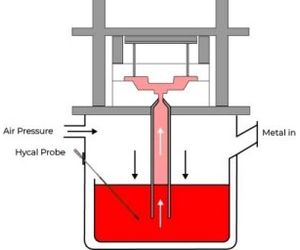

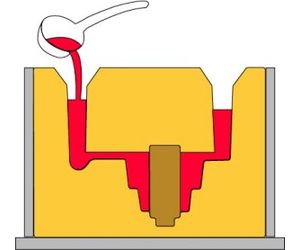

A Low Pressure Die Casting (LPDC) furnace has the additional complexity of being a sealed environment so that air pressure can be applied to force the aluminium up the riser tube into the mould above.

Hycal is unique in its ability to measure permanently in this environment by sealing to a custom flange plate with a compression fitting.

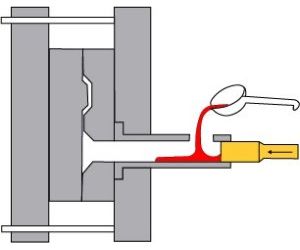

High Pressure Die Casting (HPDC) is generally thought not to suffer the same level of issues with hydrogen porosity compared to other castings methods. However, it remains necessary to control the hydrogen level as it can still have an influence of the mechanical properties such as tensile strength.

Hycal is unique in its ability to measure permanently in real-time within the degassing furnace, transfer ladle and also at the holding well at the HPDC furnace

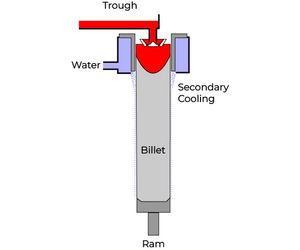

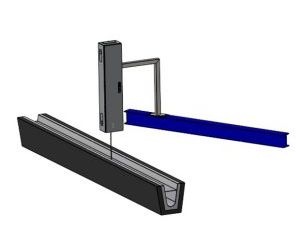

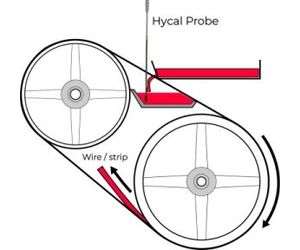

Hycal Probe Actuator located above the trough immediately prior to the casting table allows full automation and enables the entire cast to be monitored for dissolved hydrogen.

Measuring hydrogen content in the process of gravity casting aluminum is paramount to ensuring the quality and integrity of the final product. Hydrogen, when present in excessive amounts, can lead to severe defects like porosity and gas-related defects in castings.

These defects compromise the structural integrity, mechanical properties, and overall performance of the aluminum component, potentially leading to catastrophic failures in critical applications. By accurately measuring and controlling the hydrogen content throughout the casting process, manufacturers can mitigate these risks, enhance the material’s properties, and produce high-quality aluminum castings that meet stringent industry standards.

This precision not only ensures the safety and reliability of the final product but also plays a pivotal role in reducing waste and optimizing production efficiency, making hydrogen content measurement an indispensable aspect of gravity casting aluminum.

Typically, the hydrogen content of the aluminium would be measured during or just after the degassing treatment or at the holding furnace immediately prior to casting. However, due to the speed at which Hycal is able to reach equilibrium, it is also uniquely possible for Hycal to measure the hydrogen content directly within the mould itself, thereby providing a dissolved hydrogen measurement for an individual casting.

The ability to control hydrogen content in the aluminium is unique to Hycal for the following reasons:

- Hycal responds in real-time (within seconds once initial equilibrium has been reached).

- The guided degassing process can be used to program a hydrogen setpoint which will send a signal to the degassing machine telling it when to start / stop.

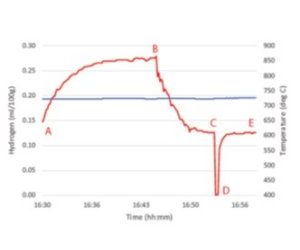

The graph below shows a ‘gassing-up’ process followed by degassing treatment, verified finally by a static measurement.

The measurement and control of hydrogen during continuous casting operations such as wire production is a critical part of the process.

Hydrogen related defects may compromise the structural integrity, mechanical properties, and electrical properties, potentially leading to catastrophic failures in critical applications. By accurately measuring and controlling the hydrogen content throughout the casting process, manufacturers can mitigate these risks, enhance the material’s properties, and produce high-quality aluminum castings that meet stringent industry standards.

The control of dissolved hydrogen in liquid aluminium alloys is a critical requirement for the aluminium industry. Aluminium producers and foundries worldwide make significant investments in capital equipment, consumables and human resources in order to ensure that the dissolved hydrogen content is within acceptable limits.

If the hydrogen level is too high, during solidification, there is the potential for the formation of cavities / pores. Conversely, a moderate hydrogen level may be desirable under certain conditions, in order to combat shrinkage porosity. As such, there is an optimum hydrogen level which ideally should be established and controlled during casting. Although dissolved hydrogen is critical, pore formation is also influenced by several other factors, the most significant being melt cleanliness i.e. the level of inclusions such as metal oxides.

Hydrogen measurement techniques such as the ‘reduced pressure test’ provide an indication of the combined effect of both the hydrogen content and the metal cleanliness. However, in order to be able to analyse the hydrogen content specifically, it is necessary to measure it directly. Furthermore, in order to control the hydrogen content, it is necessary to measure it accurately in real-time.

“The most accurate, reliable and cost-effective solution”

Real-time hydrogen analysis and control

New features…

- Integrated Mass Flow Controller

- Integrated EEPROM (plug and play)

- IP67 USB / Ethernet

- Faster. Increased accuracy

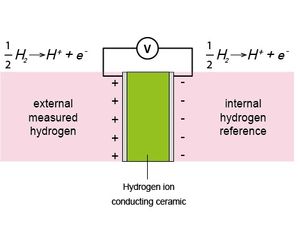

The technology is based on a novel ceramic material (CaZrO3-In) which, at an elevated temperature, is able to conduct hydrogen ions. The principle behind how this material can be used to measure hydrogen concentration is shown below:

Above, an impervious section of hydrogen ion conducting ceramic (green) is coated with metal electrodes on both faces. The concentration of electrons is higher on the right side than on the left due to the greater hydrogen concentration. This results in the right side becoming negatively charged with respect to the left.

If the voltage across the ceramic is known and the hydrogen concentration on one side is known (the “reference” hydrogen concentration), then the hydrogen concentration on the other side can be calculated. This type of arrangement is called a “hydrogen concentration cell”.

In order to be able to use a hydrogen concentration cell to measure hydrogen, the reference hydrogen concentration must be known. A patented “solid-state reference” (solid material which generates a known hydrogen concentration) is sealed within the sensor to effect this reference. The electrode exposed to the solid state reference is thus the “Reference Electrode” and the electrode exposed to the measured gas is the “Measuring Electrode”.

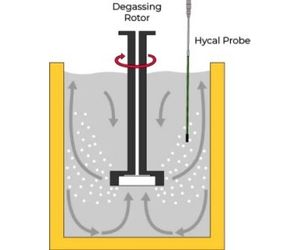

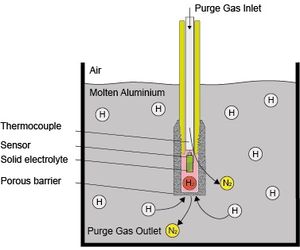

The schematic below shows the arrangement of the probe during measurement of hydrogen concentration in molten aluminium. At the end of the probe, there is a porous diffusion barrier. Hydrogen dissolved in the melt comes out of solution, and the hydrogen gas forms within the measurement chamber as shown. The measuring electrode of a hydrogen concentration cell is exposed to this gas. The voltage from the hydrogen concentration cell is measured, and as the reference hydrogen concentration is known, the concentration of hydrogen gas in the measurement chamber is calculated.

To work out the hydrogen concentration in the melt, the solubility of hydrogen must be known. The solubility of hydrogen in pure aluminium is temperature dependent. Therefore the melt temperature must also be measured to calculate the dissolved hydrogen level.

Hydrogen solubility also depends on the alloying components in the melt. In this respect, an adjustment is made to solubility factors within the analyser to compensate accordingly.

The Hycal device range has been specificaly designed to address the varied demands of distinct production environments, spanning from advanced aerospace rolling slab manufacturers to artisanal foundries.

- Portable: No external connections required whatsoever. Battery powered. Internal gas cylinder.

- Durable: Withstands arduous working environment (up to 70 deg C).

- Remote Control: Included PC software allows every function to be viewed and controlled from a remote location, such as control-room or office.

- SCADA: Easy integration into an existing SCADA system (MODBUS TCP protocol).

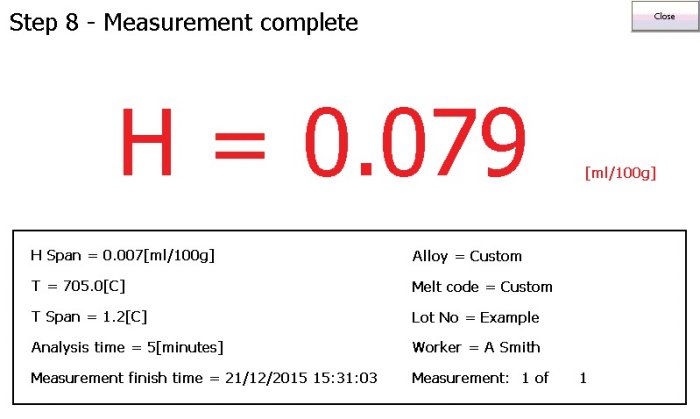

- User Interface: A sophisticated user interface has been developed specifically to meet the re- quirements of the production environment at the operator level. Security is controlled by login based access privileges (Operator / Manager / Engineer).

- OBD: Sophisticated On-Board Diagnostics constantly monitor the probe’s impedance, flow rate and internal pressure etc and outputs the appropriate alarm message with suggested remedies, should an issue arise - such as the the prompt to change probes when maximum use has been detected.

- Control: Can be used to control hydrogen during a ‘degassing’ or ‘gassing-up’ procedure. Rather than operate a treatment for a fixed amount of time, with Hycal it is possible to define a setpoint in terms of hydrogen content.

The data within the Hycal is stored in a protected format such that only validated data can be imported into the PC software thus providing data archiving security.

The software is very simple to use. All the data from multiple analysers and probes can be searched via melt code and lot number, probe number etc can be filtered thereafter. Either a graphical (shown below) or spreadsheet report can be generated.

The groundbreaking Hycal Mk1 was first introduced to the market in 2014. Since then, EMC has been engaged in relentless and continuous development to meet the market’s evolving needs.

The aluminium industry demanded a more sophisticated hydrogen analysis solution with:

- increased accuracy

- greater repeatability

- faster response

- ability to calibrate in-house

- reduced operating cost

EMC has consistently fulfilled these requirements, expanding its product range for diverse sector applications. Guided by valuable client feedback and trust, the evolution of Hycal is a journey marked by continuous progress. Discover the power of precision, reliability, and efficiency with Hycal’s exceptional range of products, meticulously designed for unrivalled performance.

Electrochemical hydrogen concentration cell

EMC has developed cutting-edge technology based on a novel ceramic material (CaZrO3-In) – an efficient hydrogen ion conductor at elevated temperatures.

The hydrogen ion-conducting ceramic enables accurate determination of hydrogen concentration in molten aluminium by developing a voltage across the cell body when subjected to a differential partial pressure of hydrogen.

Patented solid-state reference

Incorporated within the sensor is a patented “solid-state reference,” which enables the partial pressure of hydrogen to be measured without the need of an external reference gas.

Patented probe design

With a porous diffusion barrier allowing hydrogen gas to form within the measurement chamber, the measuring electrode is exposed to the measurement gas.

Unrivalled precision and accuracy

Hycal’s revolutionary technology empowers the aluminium industry with unparalleled hydrogen concentration analysis. The hydrogen concentration cell, featuring a patented “solid-state reference,” ensures precise measurements, delivering reliable data even in challenging conditions.

The innovative probe design enables accurate determination of dissolved hydrogen levels in molten aluminium, facilitating effective process control.

The advanced analyser has numerous built-in features developed and refined over many years to meet the needs of the end user in the harsh environment of the modern industrial aluminium casting facility. Whilst boasting sophisticated on-board diagnostics and highly customisable backend settings, the end-user is presented with a very simple to use, step by step guided user-interface, enabling accurate and repeatable measurements to be taken even by users with minimal experience.

The result is an indispensable solution that revolutionizes the monitoring of hydrogen concentration in molten aluminium, elevating productivity and ensuring consistently superior product quality.

Hydrogen Measurement

- Sensor type: Electrochemical. Solid-state reference.

- Unit of measurement: ml/100g [@ 20°C and 1 atm] (milliliter of hydrogen per 100 grams of liquid aluminium )

- Reproducibility: ±0.01 ml/100g or 3% of hydrogen concentration

- Response time:

- Initial result: 5 minutes typically.

- Subsequent response: < 5 seconds

- Temperature: of operation 620°C to 800°C

Mechanical

- Analyser: 340(W) x 266 (H) x 223 (D) mm. / 9 kg.

- Probe

- Standard length: 750mm.

- Maximum depth of immersion: 300mm

- Diameter: 6mm

- Probe cable (std): 1170mm

- Refillable gas bottle (300ml): Dry argon or nitrogen. Max fill pressure: 120 bar

Temperature Measurement

- Thermocouple: Type K

- Specified limits of error: 1.1 deg C or 0.4% - whichever the greater

Electrical

- Power supply (external unit): AC 85 - 265 V, 47 - 63 Hz

- Typical power consumption: < 10 W (probe heater off, battery discharging)

- Max. power consumption: 210 W (probe heater on, battery charging)

- Battery chemistry: Lithium ion

- Battery life: 8 - 14 hours (depending on screen brightness)

- Screen lighting: LED

- Screen resolution: 800 x 480 WVGA, TFT colour LCD

- Screen size: 7” (177mm) diagonal

- Touch screen type: Analogue-resistive with 4H hardness

- Ethernet interface: 10/100 Base-T, RJ45

- Communication protocol: MODBUS TCP

- USB: 2.0 full-speed (Type A)

- Operating Temperature: 0 - 60 deg C

- Humidity: 5 - 95% non-condensing