- Home

- Companies

- Sonic Drill Corporation (SDC)

- Products

- SDC - Model BTC Series - Hydraulic ...

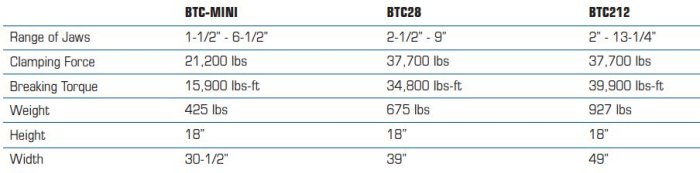

SDC - Model BTC Series -Hydraulic Breakout Wrenches

The redesigned lightweight and compact BTC Series Hydraulic Breakout Wrenches allows for hands-free operation of pipe joint breaking from the safety of the operator’s console and eliminates the need for manual tongs. Outstanding breakout torque and clamping force for faster pipe change-outs. Hardened vee-groove jaw inserts provide a full, secure grip on the pipe, increasing the service life of jaw inserts and drill pipe tool joints. An open ‘C’ shape design permits the operator to drive the rig off the drill pipe without having to push through the table. The distance between clamp tables is more compact, clamp holders receive hardened jaw inserts which are more durable and have a very low replacement cost. Jaw inserts can be installed and removed without the need of tools. Construction of rotation turret uses fewer moving parts. Easy retrofits to any drill rig. Different size adapter brackets available to accommodate any spindle to mast distance.

- Sonic Drill Corporation originated sonic drilling technology and introduced the concept to the drilling industry

- Our equipment is the result of over 25 years of extensive research and development

- We have a solid history of real world testing with machines in daily operation around the world in a variety of applications

BTC Hydraulic Breakout Wrenches:

- SDC can supply the necessary hydraulic components with schematics to best suit your rig’s hydraulic circuit

- Like all SDC products, the BTC line of tables is the result of extensive research and development in real world

- Simple proven, heavy duty construction

- Fail-safe lower clamp

- Hydraulic jaw gripping and torquing system

- Shielded hydraulic hoses

- All pinch points are fully guarded

- Engineered using (FEA) Finite Element Analysis

- Hydraulic pressure is taken from the existing system on the rig

- Hands-free, safe operation from operator’s console

- Eliminates the need for manual tongs and wrenches

- Reduces time on makeup and breakout operation

- Hardened vee-groove jaw inserts provide a full, secure grip on the pipe

- Jaw inserts are fastened into clamp holders without the need of tools

- Automatically compensates for vertical movement due to thread lead