- Home

- Companies

- Hydro Quip, Inc. (HQI)

- Products

- Hydro Quip - Model EBS Series - ...

Hydro Quip - Model EBS Series -Emulsification Breaking Separator

This all-in-one unit treats a chemical emulsion by lowering the pH, coalescing, and then neutralizing the wastewater before discharge. By destabilizing the emulsion, the oil will separate by gravity. Both mechanical and chemical emulsions can be destabilized by chemical treatment and coalescing.

Testing

The condition of the oil is probably the single most important variable the designer has to take into consideration. Before a system is designed, simple tests should be conducted to determine how to break the emulsion.

Operation

The Hydro Quip Emulsification Breaking System is an all-in-one unit designed to remove free, dispersed, and emulsified hydrocarbon products present in wastewater streams. The emulsion is broken by the adjustment of raw water pH. Oil droplets are then removed while passing through coalescing media. The final process includes chemical addition to re-adjust the product pH. The process includes motor driven mixers, chemical feed pumps, instrumentation, and controls. The separation is conducted under gravity flow.

General

Each unit shall be furnished and installed complete with: (1) Primary Reaction Chamber, (1) Solids Accumulation Zone, (1) Oil Water Separator Chamber and (1) Product pH Adjustment Chamber.

Primary Reaction Chamber

c/w (1) slow speed (350rpm) stainless steel mixer, (2) electronic chemical metering pumps, (1) pH monitoring system including a pH probe and monitor, OSHA access ladder/platform (if specified).

Solids Accumulation Zone

Sludge is collected prior to and under the coalescing media in a distinct zone with 45 degree sloped sides, baffles, and 2” threaded outlet connection.

Oil Separation Chamber

c/w Hydro Quip oil coalescing media; designed to create a quiescent zone, a laminar flow pattern to facilitate the impingement of oil on the media, and to provide numerous impact sites and changes of the flow pattern.

Product pH Adjustment Chamber

c/w (1) stainless steel mixer (1750rpm), (1) electronic chemical metering pumps, (1) pH monitoring system including a pH probe and monitor, OSHA access ladder/platform (if specified).

Control Panel

The system is provided with a NEMA 4X Control Panel mounted on the side of the EBS tank. Hand-off-auto (HOA) and on/off switches are provided for mixer and pump control; pH controllers are face mounted; and motor runlights and power on lights are also provided.

Service Conditions

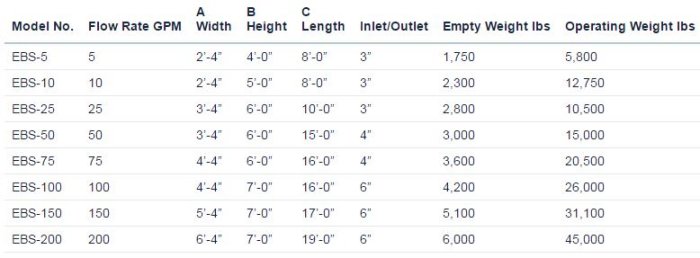

The Hydro Quip Emulsification on Breaking System is designed as a standard unit for a varied set of hydraulic conditions. Flow rates for standard units range from 5 GPM through 200 GPM.