- Home

- Companies

- Beta Control Systems, Inc.

- Products

- Beta - Hydrochloric Acid Recovery ...

Beta - Hydrochloric Acid Recovery System

Beta uses vacuum evaporation to filter contaminants and to concentrate spent hydrochloric acid for reuse. Our recovery system works continuously to maintain your acid at its optimum concentration and purity.

- Reduces acid consumption, quick return on investment

- Environmentally safe vacuum process for a clean, safe work area

- Unique heat exchange reduces energy required

- Compact design integrates into existing facilities

- High quality components & automation minimize downtime

- Materials: high temp thermoplastics, acid-impervious HX

Stap 1

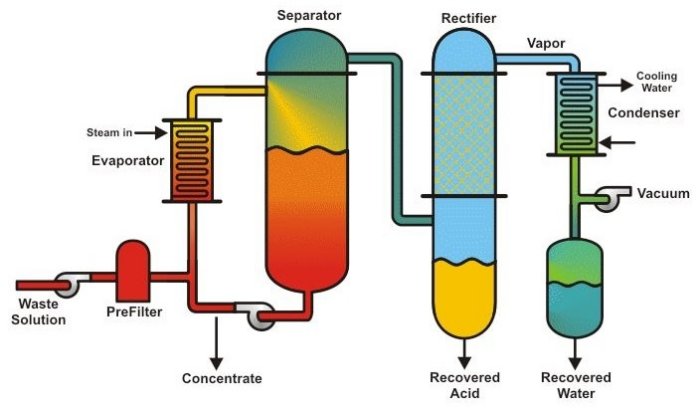

A pump forces the waste acid through a pre-filter and into the evaporator loop, comprised of the Evaporator exchanger and the Separator tank. In the evaporator loop, the HCl and water vaporize as they travel through the heat exchanger and are released into the liquid/vapor Separator. The remaining metal salt solution (metals + H2O) continues to circulate through this pressurized boiling loop until it reaches a controlled concentration and is withdrawn to a storage tank.

Stap 2

Forced by expansion, the acid and water vapors are driven from the Separator and into the Rectifier (small systems not equipped with Rectifier.) The concentration of acid is controlled in this step to return excellent quality, recovered acid to the process tank.

Stap 3

The remaining water vapor, stripped of acid, continues its journey into the Condenser where it is sub-cooled and condensed to good quality water. This water is reused as rinse water or is returned to the process tank with concentrated acid.

Stap 4

The system has no exposed metal parts and is designed to withstand a vacuum. Industrial PLC automation is used to control the process using proven software developed specifically for this application. The system requires a boiler or external heat source, cooling water, and electricity.

Remote troubleshooting assistance and closed circuit monitoring by our engineering department.

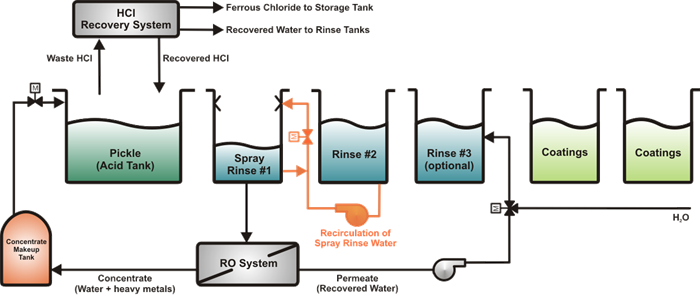

- Recycles inactive pickle liquor

- Reduces pickling times

- Recovers HCl & water for reuse

- Concentrates iron chloride co-product for potential sale

Our HCl Recovery System design provides a solid foundation for the recovery of mixed acids. Changes in materials and several components allow the recovery of other acids while protecting the system against corrosion. Our software easily accomodates the differences in evaporation temperatures and solubility. If you have a mixed acid recovery application and would like a proposal, please Request a Quote.