- Home

- Companies

- Waterline Renewal Technologies.

- Products

- Insignia - Hydrophilic Connection Hat

Insignia - Hydrophilic Connection Hat

The Insignia Hydrophilic Connection Hat is utilized to provide a positive compression seal at the main/lateral junction of a sewer collection system. This hat is a 360 degree sealing gasket that prevents water tracking behind the liner at the main/lateral junction of a collection system where the maximum amount of Infiltration and Inflow (I&I) occurs. The Insignia Hydrophilic Connection Hat creates a seal at the main source of infiltration ensuring that this sealing technology, along with a structural CIPP repair is the most effective solution for rehabilitating the main/lateral connection. The Insignia product line used in conjunction with CIPP lining is more than just a structural repair, it’s a water-tight, sealed system! The Insignia Hats are compatible with Inversion and Pull-in-place lining methods.

Lasting and Measurable Results

The Insignia product line is manufactured using a type of hydrophilic rubber material “Neoprene” which continues to expand in the presence of water until a compression gasket seal is formed. It is also one of the strongest and most durable materials that is used in many water-proofing applications today. Application of the Insignia Seals guarantees a flexible, leak free, structural repair of the sewer collection system.

360 Degree Swelling Gasket

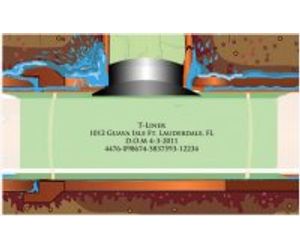

The Insignia Hydrophilic Connection Hat is a one-piece hydrophilic hat gasket that is installed at the main/lateral connection precisely at the source of the Infiltration and Inflow (I&I). The Insignia Connection Hat is a 360 degree hat that is secured onto the liner during the installation process to ensure there is no movement of the hat during installation. Due to this placement and the special design of the hat, the I&I is not allowed to track back into the system resulting in a sealed system.

Seamless 3D Molding

The design of the Insignia Hydrophilic Connection Hat is streamlined and custom fitted to the liner. These hats are seamless and have a “cat’s eye” like opening into the lateral which upon application of air pressure during the process of inversion expands to fit the circular shape of the pipe. The Insignia Hydrophilic Connection Hat boasts a uniform thickness along the seal for maximum I&I reduction at the main/lateral junction. In addition, the gasket seals the end of the lateral liner at the main/lateral junction.

The INSIGNIA Connection Hat is attached to the inner portion of liner at the main/ lateral junction after it has been resin-saturated and loaded onto the launching device. The launching device is then robtically positioned in the main pipe. Air pressure is applied and the main portion inflates causing the lateral portion to invert. This presses the INSIGNIA Connection Hat up into the main/lateral junction and secures it between the liner and host pipe. After 24 hours the INSIGNIA connection hat swells creating a positive compression seal.

LMK`S INSIGNIA is manufactured using Neoprene which is a synthetic rubber made from polymers of chloroprene. Neoprene is an extremely durable and chemically inert product that is commonly used in waterproofing applications because of its insulation properties. Pictured left and right is a cured in place liner with INSIGNIA O-Rings.