- Home

- Companies

- Flowplant Group Limited

- Products

- Flowplant - Hydrostatic Test Rigs

Flowplant - Hydrostatic Test Rigs

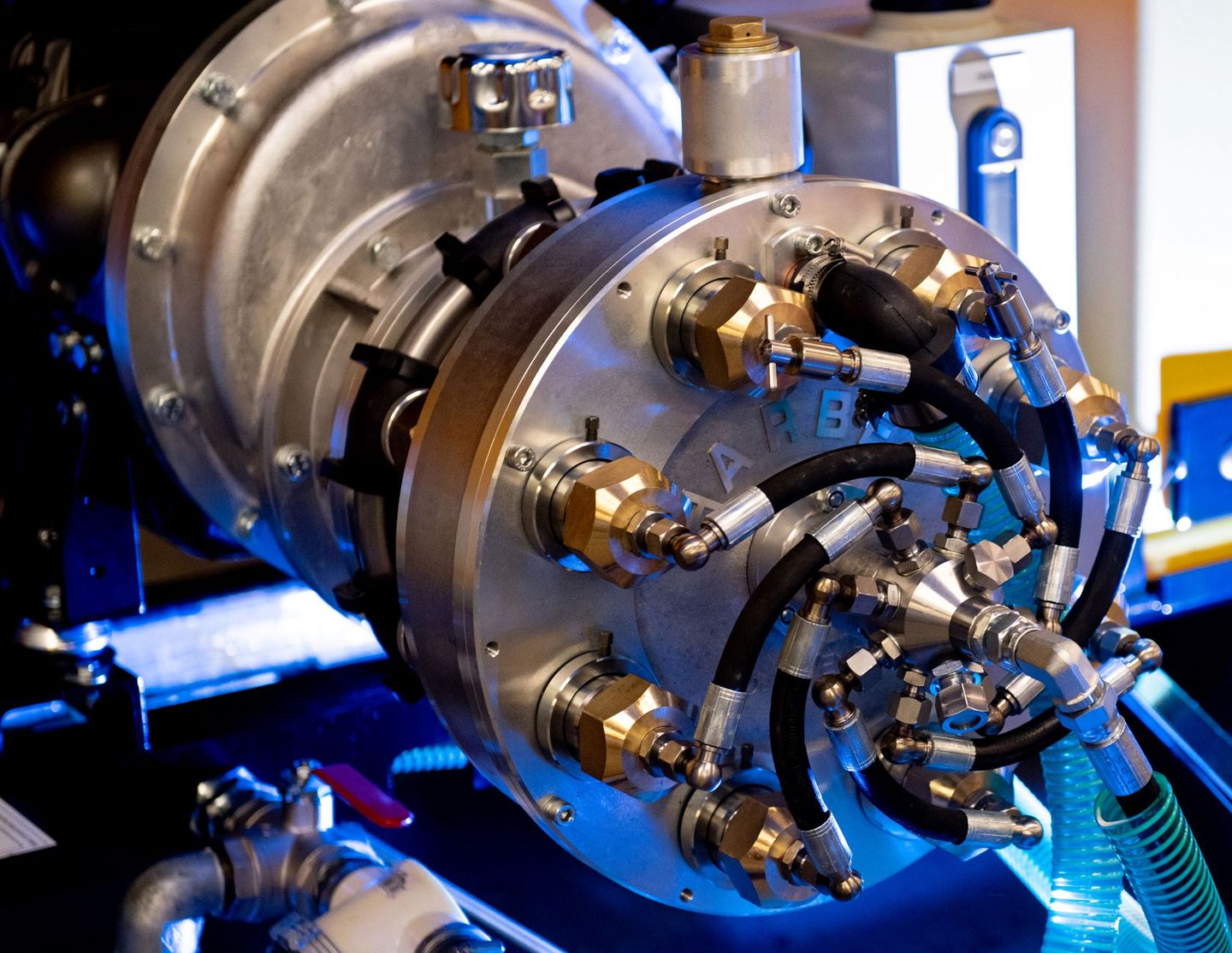

Flowplant manufacture a range of high flow hydrostatic test rigs. We specialise in building units that combine a fast filling function with a final high pressure test. This often requires integration of several different pumps onto a single skid. Our hydrostatic test rigs often have a high flow centrifugal pump for quick prefill, a triplex plunger pump for a medium pressure test and possibly an intensifier for a final high pressure test. Adopting this integrated approach can provide, for example, a unit capable of 10m3/hr at 10 bar all the way up to 200l/hr at 1,400 bar. If pressure control needs to be monitored, adjusted or recorded from a remote location we can offer solutions to cover all aspects.

The Flowplant range of fast fill and test rigs have been deployed on many sites and vessels in the last 30 years where our Aqua® triplex pump and Harben radial diaphragm pumps have operated reliably and economically. It is common for such systems to use sea water for testing and Flowplant has developed corrosion resistant fluid heads and valves to prolong service life and reduce downtime.

The Flowplant skid range offers a complete solution for all pipe and vessel hydrotesting tasks. If, however, you need a bespoke system please give us a call. We will work with you to ensure you get exactly the system you need.

We are also able to offer a complete set of complimentary products such as test manifolds and integrated chart recorder systems that will provide a permanent log of results achieved.

- Hydrostatic testing of pipes & vessels both onshore & offshore

- Fast filling pump options e.g. 50m3/hr @ 10.3 Bar

- Mid pressure system options e.g. 300 Bar @ 150 l/min

- Hydrostatic air driven test pump e.g. 400 l/hr @ 1034 Bar

Model: Hydrostatic Test Rigs (example specification)

- Pressure and Flow (examples)

- Filling (FS): 50m3/hrm @ 10.3 Bar

- Mid pressure system (MPS): 180 lpm @ 210 Bar

- Hydrostatic test pump (HTU): 400 lph @ 1034 Bar

- Pump:

- Aqua AHF 215 three cylinder positive displacement plunger pump/Harben radial diaphragm pump

- Air driven hydrostatic test pump dual piston 1034 Bar

- Chemical Injection: Optional automated and manual chemical injection available on both fill and test systems

- Motor/Starter: Motors are IP55 rated for ingress protection. Star Delta 90kW motor controlled via Red Lion HMI.

- Control System: Remote control available with full downloadable data logger availability and touch screen operation

- Services Required: Air supply: 9 Bar @ 400 scfm

- Electrical supply: 440v 3 phase 60 Hz (other options available upon request)

- Sea water: FS pump flooded capable of 50m3/hr flooded

- Pressure Relief Valve: PRV set to 10% WP. Lloyd’s Register certification available upon request.

- Pressure Regulating Valve: Pneumatic operated pressure regulating valve controlled via Red Lion HMI

- Sampling: Fluid sampling on tank, pressure line and return

- Supply Tank: 1000 litre supply tank manufactured from 316 stainless steel. Full temperature and level monitoring via HMI.

- Cooling: Dump pump capable of emptying tank at 180 lpm

- Frame: Mild steel SHS tested and certified to 1.5 SWL. Supplied with approved lifting eyes for transportation.

- Filtration: 50 micron inline filter to supply tank.

- Dimensions: 3500mm Long x 1800mm Wide x 2000mm High **

- Weight: Dry weight: From 3600 kgs **