- Home

- Companies

- AGO Hydroair GmbH

- Products

- Ice Prevention Systems Powered With ...

Ice Prevention Systems Powered With Compressed Air

Protection for marinas, jettys, navigation channels, flood gates and other hydraulic engineerings against ice damage. Our ice prevention plants are optimised for a safe protection of hydraulic engineerings from ice damage. For example one can protect the jettys of harbours with bubble curtains around the construction against ice damage. The installation and the operation of such ice prevention systems is generally by far more inexpensive, than the construction of winterproof hydraulic buildings.

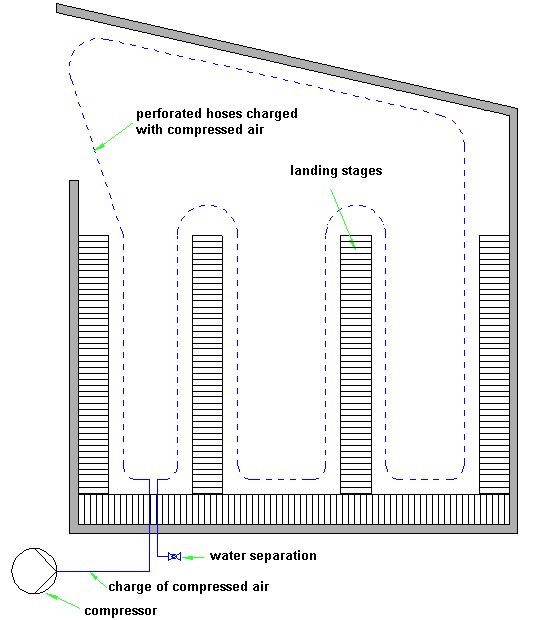

Curtains of air bubbles are produced by perforated hoses fixed at the bottom of the waters and attached to compressed air. The bubbles climbing up from the perforated hoses and tear the water with them upward.

As well known water has its largest specific density at +4°C. In the winter standing waters with frozen surfaces aim this temperature level in the depth. Thus the ascending bubbles carry the warmer depth water to the surface where the ice formation is then prevented.

The hole diameter, hole spacing and the hose diameter will measure in such a way under use of a computational program that air flow is constant or varying over the length of the ice-free distance depending upon the requirements.

For the dimensioning of a compressed air ice-free retaining plant the heat balance of waters is important. An ice prevention plant must be laid out in such a way that the heat transfer between water bottom and the surrounding water layers runs off substantially more slowly than the heat transfer from the water surface to the atmosphere. So that the available warmer water is not too fast used and thus the transport of the warmer bottom water may be controlled small, as it is absolutely necessary for the prevention of the ice formation.

The equipment necessary for ice preventing system covers:

- A compressor (oil-free) or blower

- A final cooler with condensate separator because the hose, which consists of plastic, may not be exposed to hot compressed air

- Compressed air supply lines from galvanized steel or PE from compressor or blower to the water bottom

- Perforated hoses and anchor weights

- Locking off and regulating units

- Ice/frost sensors for the automatic monitoring of waters

- Remote transmission for alert, check and maintenance