- Home

- Companies

- Baltimore Aircoil Company

- Products

- BAC - Model TSU-C/D - Ice Thermal ...

BAC - Model TSU-C/D -Ice Thermal Storage Tanks

Reliability: constant water supply temperature (1 to 2°C). Lowest first cost. Energy saving. Minimum maintenance. Environmentally friendly. Proven technology

- External ice melt

- Direct refrigerant or glycol feed

325 - 5060 kWh

Typical applications- Food processing

- Breweries

- Dairies

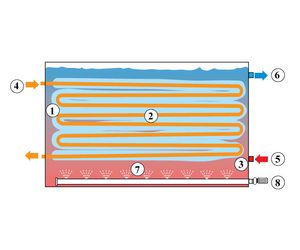

The TSU-C/D is an external melt system that produces and builds ice (1) around a coil (2) submerged in water (3). A refrigerant or cold glycol (4) circulates through this, while ice accumulates on the outside. The ice is melted by circulating warm water (5) from the load over the coil, which cools the water (6). Low pressure air (7) from an air pump (8) is distributed below the coil for water agitation.

Material options

- Tank is constructed of heavy-gauge hot-dip galvanized steel for unit steel panels and structural elements, all with welded seams. Tank includes high quality insulation.

- Insulated watertight tank covers and exterior tank panels featuring Baltibond hybrid coating .

Coil

The coil is constructed of continuous length of prime surface steel, hot-dip galvanized after fabrication. Designed for maximum 10 bar (glycol ) or 22 bar (ammonia) operating pressure according to PED.

Construction

- Factory assembled construction (except air pump).

- Air distribution system consists of multiple perforated PVC pipes and air pump.

- Ice logic ice thickness controller (option): sensor on coil for deactivation of refrigerant compressor at full ice build.